Opt. 006 Define Measurement

This topic describes the measurement dialogs displayed based on the

instrument and fixture.

In this topic:

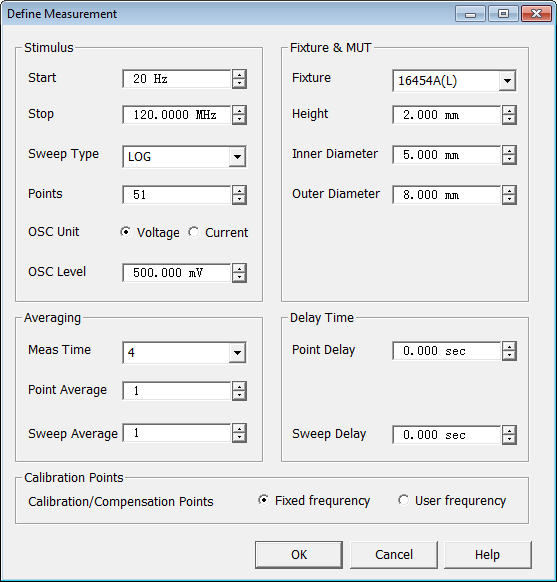

Click Calibration then Define Measurement to display the

Define Measurement dialog.

Impedance Trace Data Types

Fixture |

Impedance

Trace Data Type |

16451B (contact method)

|

Cp and D |

16451B (non-contact method)

|

Cp, D, Cpg, and Dg. Cpg and Dg

are the results when the MUT is not inserted. |

16452A |

Cp, G, C0, and G0. C0 and G0

are the results of air capacitance measurement. |

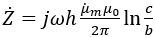

16454A |

R,

X, MUT_R, and MUT_X. MUT_R and MUT_X are calculated impedance

when ideal one-turn coil is built on the MUT with defined dimension

that has rectangular cross-sectional shape, which is defined as

Where,

is measured

complex permeability value of MUT

is measured

complex permeability value of MUT

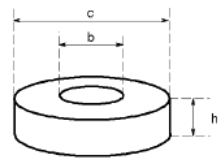

b

is inner diameter of MUT

c

is outer diameter of MUT

h is height of MUT |

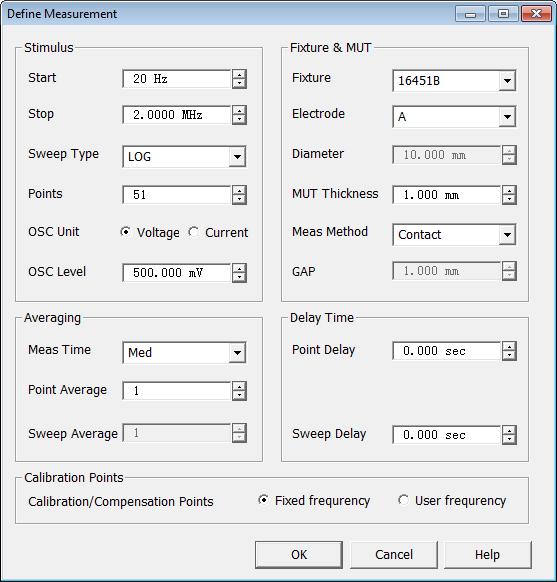

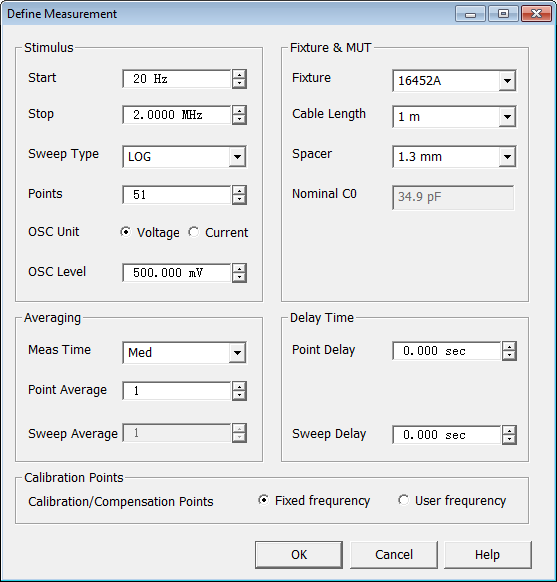

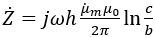

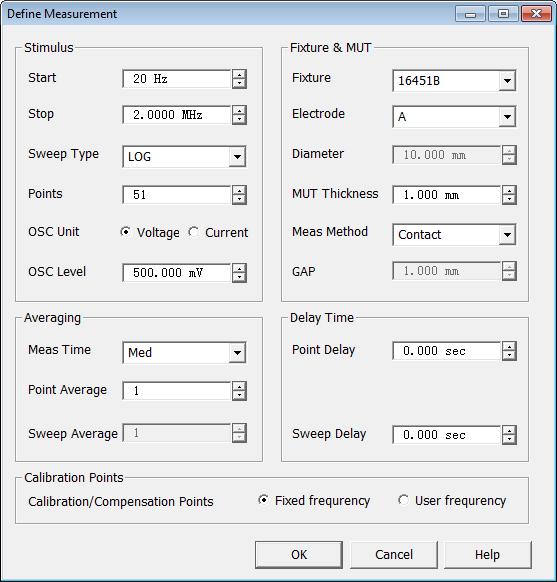

E4980A/AL with 16451B/16452A

16451B |

16452A |

|

|

Stimulus

Start

- Enter the start frequency using the up/down arrows or double-click in

the field to open the numeric keypad.

Stop

- Enter the stop frequency using the up/down arrows or double-click in

the field to open the numeric keypad.

Sweep Type

- Select LOG or LIN

sweep type.

Points

- Enter the number of measurement points using the up/down arrows or double-click

in the field to open the numeric keypad.

OSC Unit

- Set oscillator test signal to voltage or current.

OSC Level

- Set oscillator test signal level using the up/down arrows or double-click

in the field to open the numeric keypad.

Fixture & MUT

Fixture

- Select the fixture.

16451B

only

Electrode

- Select the fixture electrode.

Electrode

Diameter - Enter the electrode diameter using the up/down arrows

or double-click in the field to open the numeric keypad.

MUT Thickness

- Enter the MUT thickness using the up/down arrows or double-click in

the field to open the numeric keypad.

Meas Method

- Select Contact or Non

Contact measurement method.

GAP

- Distance between upper and lower electrodes.

16452A only

Cable Length

- Enter the cable length using the up/down arrows or double-click in the

field to open the numeric keypad.

Spacer

- Enter the spacer width using the up/down arrows or double-click in the

field to open the numeric keypad.

Nominal

C0 - Displays the typical

air capacitance value when measuring the C0 with selected spacer. The

expected value is +/- 10 to 25%. Refer to the 16452A operation and service

manual for details.

Averaging

Meas Time - Select from:

Short - Shortens the measurement

time.

Med - Sets the measurement time

between Short and Long.

Long. - Lengthens the measurement

time.

Point Average

- Sets the number of data points to average using the up/down arrows or

double-click in the field to open the numeric keypad.

Sweep Average

- (Not available on E4980A)

Delay Time

Point Delay

- Sets the time to wait between measurement points using the up/down arrows

or double-click in the field to open the numeric keypad.

Sweep Delay

- Sets the time to wait between measurement sweeps using the up/down arrows

or double-click in the field to open the numeric keypad.

Calibration Points - Select

the type of calibration frequency points to use in obtaining calibration

data.

Fixed frequency

- Obtain calibration/compensation data at fixed frequency points covering

the entire frequency range of the instrument. In measurement, user calibration

or fixture compensation is applied to each measurement point by using

interpolation. Even if the measurement points are changed by altering

the sweep setups, you don't need to retake the calibration/compensation

data.

User frequency

- Obtain calibration/compensation data at the same frequency points as

used in actual measurement, which are determined by the sweep setups.

Each set of calibration/compensation data is applied to each measurement

at the same point. If measurement points are changed by altering the sweep

setups, calibration/compensation data become invalid and calibration/compensation

data acquisition is again required.

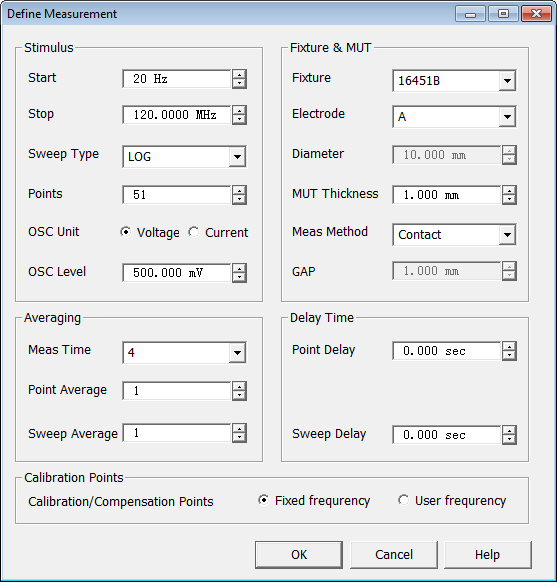

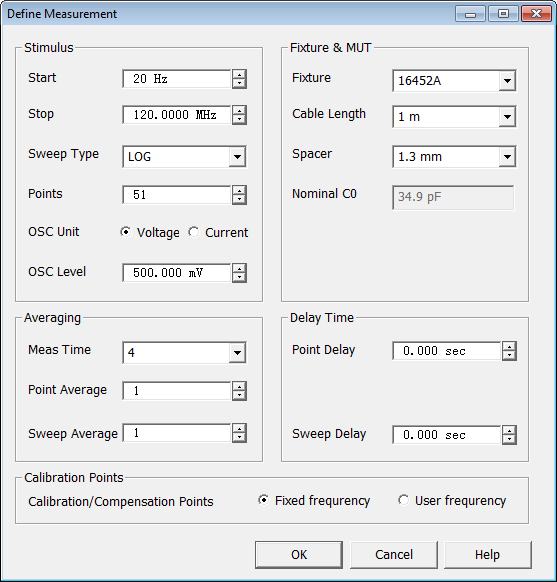

E4990A with 16451B/16452A/16454A

Note: The E4990A

Option 120 using the 42942A adapter is required with the 16454A fixture.

Stimulus

Start

- Enter the start frequency using the up/down arrows or double-click in

the field to open the numeric keypad.

Stop

- Enter the stop frequency using the up/down arrows or double-click in

the field to open the numeric keypad.

Sweep Type

- Select LOG or LIN

sweep type.

Points

- Enter the number of measurement points using the up/down arrows or double-click

in the field to open the numeric keypad.

OSC Unit

- Set oscillator test signal to voltage or current.

OSC Level

- Set oscillator test signal level using the up/down arrows or double-click

in the field to open the numeric keypad.

Fixture & MUT

Fixture

- Select the fixture.

Note:

For the 16454A fixture, a large (16454A(L))

or small (16454A(S)) fixture can

be selected.

16451B

only

Electrode

- Select the fixture electrode.

Diameter

- Enter the MUT diameter using the up/down arrows or double-click in the

field to open the numeric keypad.

MUT Thickness

- Enter the MUT thickness using the up/down arrows or double-click in

the field to open the numeric keypad.

Meas Method

- Select Contact or Non

Contact measurement method.

GAP

- Distance between upper and lower electrodes.

16452A only

Cable Length

- Enter the cable length using the up/down arrows or double-click in the

field to open the numeric keypad.

Spacer

- Enter the spacer width using the up/down arrows or double-click in the

field to open the numeric keypad.

Nominal

C0 - Displays the typical

air capacitance value when measuring the C0 with selected spacer. The

expected value is +/- 10 to 25%. Refer to the 16452A operation and service

manual for details.

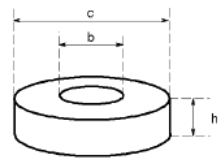

16454A only

Note:

You must enter the MUT dimensions before a measurement can be performed. Use a micrometer or calipers to

measure the outer (shown as c in the below figure) and inner (shown as

b in the below figure) diameters and height (shown as h in the below figure).

Height

- Enter the height of the MUT using the up/down arrows or double-click

in the field to open the numeric keypad.

Inner Diameter

- Enter the inner diameter of the MUT using the up/down arrows or double-click

in the field to open the numeric keypad.

Outer Diameter

- Enter the outer diameter of the MUT using the up/down arrows or double-click

in the field to open the numeric keypad.

Averaging

Meas Time - Sets measurement time

to 1 (fastest), 2, 3, 4, or 5 (slowest and more precise).

Point Average

- Sets the number of data points to average using the up/down arrows or

double-click in the field to open the numeric keypad.

Sweep Average

- Sets the number of sweeps to average using the up/down arrows or double-click

in the field to open the numeric keypad.

Delay Time

Point Delay

- Sets the time to wait between measurement points using the up/down arrows

or double-click in the field to open the numeric keypad.

Sweep Delay

- Sets the time to wait between measurement sweeps using the up/down arrows

or double-click in the field to open the numeric keypad.

Calibration Points - Select

the type of calibration frequency points to use in obtaining calibration

data.

Fixed frequency

- Obtain calibration/compensation data at fixed frequency points covering

the entire frequency range of the instrument. In measurement, user calibration

or fixture compensation is applied to each measurement point by using

interpolation. Even if the measurement points are changed by altering

the sweep setups, you don't need to retake the calibration/compensation

data.

User frequency

- Obtain calibration/compensation data at the same frequency points as

used in actual measurement, which are determined by the sweep setups.

Each set of calibration/compensation data is applied to each measurement

at the same point. If measurement points are changed by altering the sweep

setups, calibration/compensation data become invalid and calibration/compensation

data acquisition is again required.

![]() is measured

complex permeability value of MUT

is measured

complex permeability value of MUT