Metrology Stability Performance Test

(Option 210 or 410 only)

This test applies to the following models:

-

N5221A/AS/B, N5222A/AS/B, N5224A/AS/B, N5225A/AS/B, N5227A/AS/B with Option 210 or 410

|

|

-

Although possible, running the metrology stability routine on a 4-port PNA as a 2-port is not supported by TME. A 4-port PNA must be tested as a 4-port with a separate ECal module for each port. A 2-port PNA must be tested as a 2-port with a separate ECal module for each port.

-

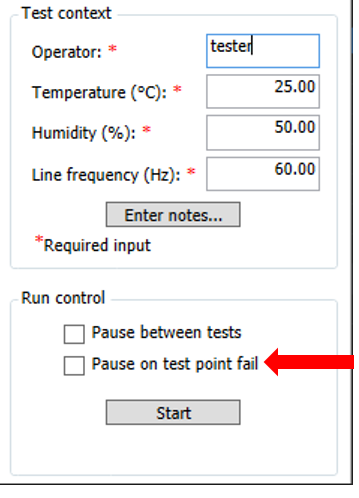

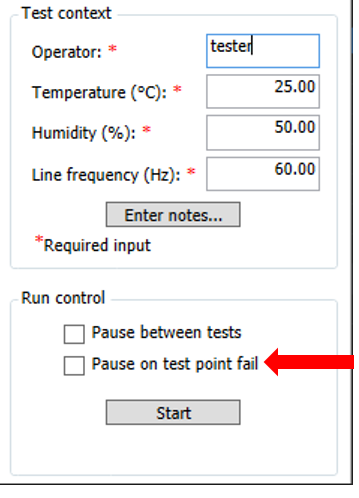

Be sure that  Pause on test point fail is not selected for this test. Pause on test point fail is not selected for this test.

|

The PNA metrology Options 210 (for 2-port) and 410 (for 4-port) provide improved match performance and measurement stability over time, and is designed primarily for precision S-parameter measurements of metrology-grade components.

This test is designed to test the stability of the PNA in terms of S-parameter by analyzing the drift in error term within 24-hours in a temperature and humidity-controlled environment. The drift error is mainly due to variations in the systemic errors over time and/or temperature.

Typically, testing requires several days to complete—two days for warmup and one for running the test. All results are stored to the PNA's metrology folder (D:\Metrology for A-models, E:\Metrology for B-models).

The actual test is run outside of the Test Measurement Environment. TME will be used to generate and access the reports of the metrology routine. This service routine can be found under the PNA menu: Utility → System → Service → Metrology, or at C:\Program Files (x86)\Keysight\Network Analyzer\Service\.

Ecal Modules

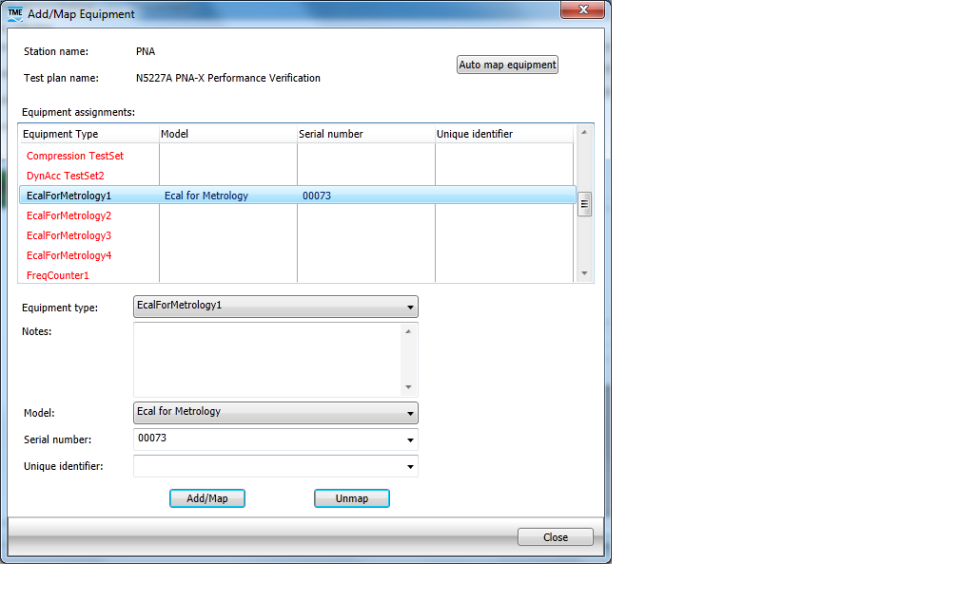

In order for TME to generate a traceable report, the following data regarding the ECal modules used in the metrology service routine must be entered into the TME test configuration station:

-

calibration due date of each ECal module — found on the module label

-

serial number of each ECal module — For 2-port PNA, two serial numbers will be entered; if 4-port PNA, four serial numbers will be entered. The serial numbers can be found on the label on the module itself, or in the LogInfo.txt file of the PNA's metrology folder (D:\Metrology for A-models, E:\Metrology for B-models) explained in the next section.

|

|

When entering the ECal module serial number in TME, be sure to enter the 5-digit serial number for the module (not the 10-digit number for the kit). Refer to the E-Cal Module Troubleshooting page for more information.

|

Test Reports and Files

There are two important files located in the PNA's metrology folder (D:\Metrology for A-models, E:\Metrology for B-models). Both can be read using a basic text editor such as Notepad®. These files will be located in a sub-folder named by the date that the test was run on the PNA. Start with the most recently dated folder first.

-

The _Max.sNp file (for example: T0906_Max.s2p) — This file indicates that the test was successfully run. If this file is not in the folder, then proceed to the next most recently-dated folder, working backwards in time until the _Max.sNp file is located. If the file cannot be found in any of the dated folders, then the Metrology Utility Test must be re-run from the PNA in the chamber environment.

-

LogInfo.txt — Contains basic information about the test including the serial numbers (shown in the red box) of the ECal modules used which will be entered into TME. The example file below shows the test was run on a 2-port PNA and therefore provides the serial numbers for two ECal modules. If the PNA has 4-ports, the test will show four ECal module serial numbers, one for each port.

|

|

It's important to use the LogInfo.txt file located in the same directory that contains the Max.sNp file AND is in the most recently dated folder. The Max.sNp file indicates the test was successful. Other dated folders in PNA's metrology folder (D:\Metrology for A-models, E:\Metrology for B-models) may also contain a LogInfo.txt file, but the information in the file will not be valid for TME unless there is also a Max.sNp file to indicate that the test was successful. The LogInfo.txt file must come from the most-recently dated folder that also has a Max.sNp file.

|

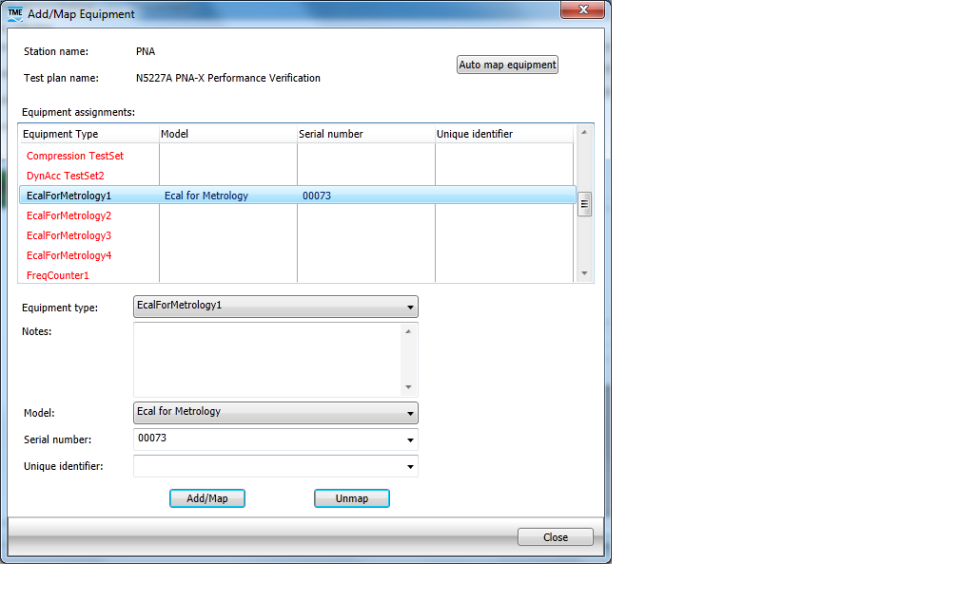

Below is a sample of the Add/Map Equipment window of TME where the ECal modules are mapped. The serial numbers for the ECal modules are entered into TME. They are found on the ECal module label or in the LogInfo.txt file located in the PNA's metrology folder (D:\Metrology for A-models, E:\Metrology for B-models).

Below is a sample of the Test Equipment Summary page.

|

|

The Test Date shown in this report is the date of when TME generated the reports which can be different than the date of when the actual Metrology Utility Test was run on the PNA in the chamber environment.

|

Below is a sample of the Environmental Conditions report. Notice that Humidity and Line Frequency both show as Unavailable as these variables are not factored into the test reports.

In the Environmental Conditions report above, the the Temperature is shown as See Temp vs Time Pages. Below is a sample of the Temp vs Time graph. This is used for reference only and can be helpful to troubleshoot a failed test since temperature stability is extremely important to the success of the metrology test.

Below is a sample of the TME test report. The date located in the NOTE at the end of each S-parameter report is when the actual metrology utility test was run on the PNA in the chamber environment.

Pause on test point fail is not selected for this test.

Pause on test point fail is not selected for this test.