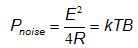

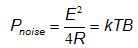

Noise Floor, as defined here, is the absolute measure of the average power signal (noise) at a receiver where there is no expected signal and the receiver has its input loaded in a matched Zo load. The signal that is being measured is assumed to be thermal noise generated within the receiver system and as such has the relationship:

where:

E is the noise voltage,

k is Boltzmann’s constant,

T is the absolute temperature in Kelvins

R is the receiver resistive component in ohms,

B is the bandwidth in hertz.

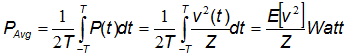

By definition the (time) average power of a signal is found, using the equation for power as a function of voltage and impedance, as:

where v(t) is the time varying voltage, Z is the impedance across which v(t) is varying, and T is an integral number of half periods. Averaging the square of the voltage over time derives the expression to the far right or the statistical Expectation (mean square value) of v(t).

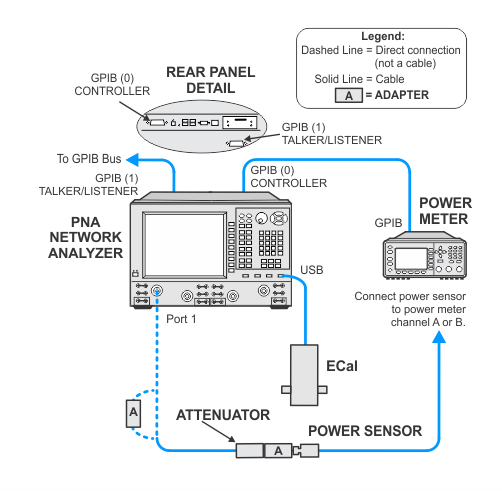

The signal for the receiver correction measurement comes from one of the VNA ports. The power level must be accurately measured at the point it will be injected in the receiver. Since the VNA source has high harmonic content, a broadband power sensor cannot be used to measure this power level. Therefore, a SmartCal procedure called PNAasPowerMeter will be used to make an external PNA behave as a tuned power meter. The data from the SmartCal can be recalled from a previous test providing it's within four hours and the cable and attenuator connections have not been disturbed. Otherwise the PNAasPowerMeter calibration procedure must be repeated. Refer to Connections and Setup Procedures below for more information.

Click here for troubleshooting help.

|

|

TME will present a prompt that offers the user the choice to perform the calibration before starting the test at hand even if it's been within the allowed timeframe. Existing data can be used, if available. For troubleshooting, it is recommended to re-do the calibration especially if you are unsure if the adapter/cable/attenuator setup has been disturbed or disconnected. |

|

Test Equipment |

Recommended Models1 |

|---|---|

|

PNA network analyzer |

N5245B |

|

Attenuator, 10 dB |

8493C Option 010 |

|

Power meter 2 |

N1914A |

|

Power sensor 2 |

N8485A |

|

Attenuator, 10 dB |

8493C Option 010 |

|

ECal module, 3.5 mm |

N4691D3 Option M0F |

|

Calibration kit, 3.5 mm |

85052B |

|

Cable, 3.5 mm (m) to 3.5 mm (f) |

8121-2111 |

|

Adapter, 3.5 mm (f) to 3.5 mm (f) |

83059B |

|

|

|

To ensure best test results, use a good quality cable, adapter, and attenuator. Do not disturb the adapter/cable/attenuator setup attached to the PNA. Because the data from the PNAasPowerMeter calibration is stored and re-used by other tests, it is important that the most accurate data is achieved by following these practices. |

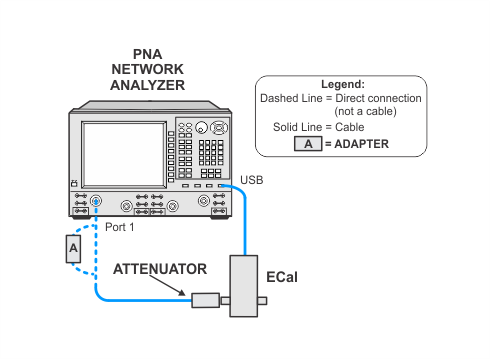

This test uses a procedure called PNAasPowerMeter. A calibrated PNA receiver will be used as the filtered power level measurement standard. This receiver is a combination of a PNA with a cable connected to one of the test ports, and a 10 dB attenuator connected to the end of the test cable. The attenuator is used to minimize the measurement uncertainty due to the VNA port mismatch.

Unless recalling stored data from a previously run PNAasPowerMeter procedure, or if the cable, adapter, or attenuator attached to the PNA has been disturbed, this process must be performed prior to running the test.

This test will use flexible power sensor channel assignment that will identify the channel that a power sensor is connected to using the ability of "smart" sensors such as the N848xA series power sensors to report their full model and serial number. Therefore it is important to keep the power sensor on the channel where it was calibrated throughout the test procedures.

Click on the drop-down links below to view setup images.

|

|

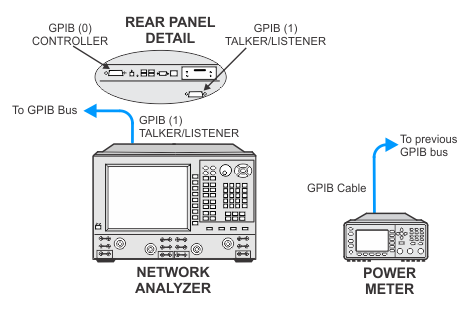

The illustrations below show details of the GPIB connections of the power meter and the PNA. After the power sensor calibration, the PNA will directly control the power meter through the GPIB cable. In order for this to occur, be sure when making the GPIB connections to:

|