Other topics about Temperature Characteristic test Kit (Option 007)

Executing the temperature compensation feature will reduce an error due to temperature change. The temperature compensation feature uses reference data to compensate an error that may be related to the measuring cable exposed to temperature change. Prior to compensation, the reference data is prepared by obtaining variation of measurement values of the open/short standards (heat-resistant) relative to normal temperature. The data will be obtained for all temperatures to be measured.

You can perform temperature compensation more easily using the Excel VBA sample program (Tctest.xlsm) that performs temperature compensation. In particular, when you use ESPEC SU-262 as a temperature chamber, you can use the attached sample program without any modification. For more information, refer to Measuring Temperature Characteristics Using Sample Program.

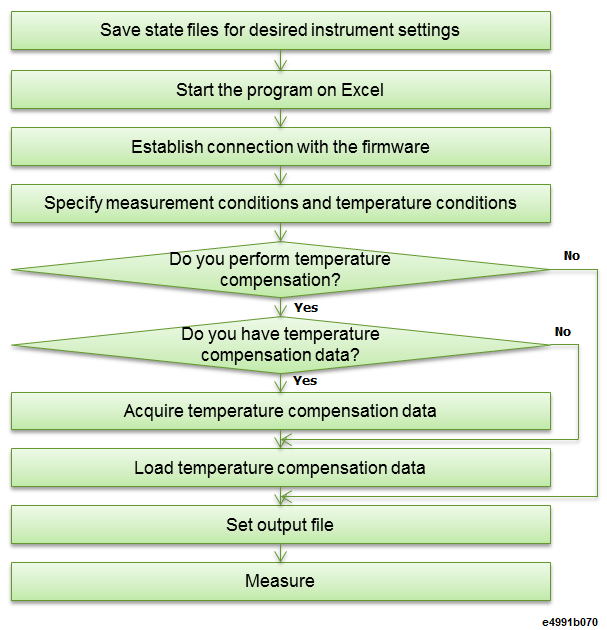

Follow the temperature compensation flow shown below:

Acquire temperature compensation data for the temperature you want to measure and save it in a file. For more information, refer to Acquiring Temperature Compensation Data.

Execute measurement at a desired temperature.

Execute the temperature compensation with the measurement result using the program for compensation.

You need to acquire temperature compensation data for all temperature points at which you want to make measurement. The temperature compensation data is the difference at each temperature between admittance measurement data for the open standard/impedance measurement data for the short standard and the reference data (measurement data for the open/short standard measured within the temperature range of 18°C to 28°C).

When the DC bias feature (option) is provided, turn the feature off while acquiring temperature compensation data.

Make sure that the temperature of the E4991B itself and tip of the measurement cable is within 18°C to 28°C and execute the open/short/load calibrations at the tip of the measurement cable (7-mm port) in the fixed frequency point mode.

Do not change the wiring layout of the measurement cable after executing calibration.

Set the desired temperature points at which you want to acquire temperature compensation data, using :SENS:CORR:TCOM:COLL:TEMP.

Measure the open standard.

Connect the heat-resistant open standard to the tip of the measurement cable.

After putting the temperature chamber (the tip of the measurement cable) to the temperature at which you want to acquire temperature compensation data, wait for at least 30 minutes (until the temperature becomes sufficiently stable) after the temperate is reached.

Measure the open standard, using :SENS:CORR:COLL:ACQ:OPEN.

For each measurement temperature, repeat c and d.

Measure the short standard.

Connect the heat-resistant short standard to the tip of the measurement cable.

After putting the temperature chamber (the tip of the measurement cable) to the temperature at which you want to acquire temperature compensation data, wait for at least 30 minutes (until the temperature becomes sufficiently stable) after the temperate is reached.

Measure the short standard, using :SENS:CORR:COLL:ACQ:SHOR.

For each measurement temperature, repeat d and e.

Complete the data acquisition, using :SENS:CORR:COLL:SAVE.

If you want to reuse the measured compensation data, save the compensation data into a file using :SENS:CORR:TCOM:STOR.

To recall the file, press Cal > Temp Compen (For Option 007) > Import From CPN File....

Temp Compen (For Option 007) is activated only when calibration is turned on.

After putting the temperature chamber (the tip of the measurement cable) to the temperature at which you want to measure the DUT, wait for at least 30 minutes (until the temperature becomes sufficiently stable) after the temperature is reached.

Press Cal > Temp Compen (For Option 007) > Temperature and input the desired temperature value.

Press Cal > Temp Compen (For Option 007) > Correction to execute temperature compensation.

The Excel VBA program for temperature characteristic measurement, TcTest.xlsm, is stored in the following folder at the factory.

D:\Tctest

This program includes 2 macros: Temperature Characteristic Test and Temperature Change Compensation.

Temperature Characteristic Test enables you to control the temperature chamber and the E4991B and measure the temperature characteristic of the DUT automatically under 3 different kinds of measurement conditions that are programmed. It also allows you to obtain temperature compensation data to decrease errors due to temperature changes and reflect it to the measurement result of the temperature characteristic, as necessary.

This sample program is created assuming that the recommended temperature chamber (ESPEC SU-262) is used, therefore, when you use ESPEC SU-262, it can be used without any modifications. If you use a temperature chamber other than the ESPEC SU-262, you have to modify the program.

Temperature Change Compensation enables you to perform temperature compensation using temperature compensation data you obtained in advance.

You can execute the test program if you have Excel installed in your unit. By default, run the sample program from external PC connected to your unit.

Prior to measurement, check the following items relating to the temperature chamber and E4991B.

Temperature chamber - Using a temperature chamber other than the ESPEC SU-262 will require the program to be modified.

GPIB address of the temperature chamber - The GPIB address setting of the temperature chamber when using Tctest.start is "1." Using a GPIB address other than "1" will require the program to be modified.

Copy the directory D:\Tctest and all its contents to your external PC using a USB memory.

Refer to the below flowchart for the overview of the measurement operation.

|

File Type |

File Extension |

File Location |

Directory (at default setting) |

|

Temperature Profile |

.tpr |

Control PC |

[Current Directory] |

|

Program Setup |

.hed |

Control PC |

[Current Directory] |

|

Measurement Result |

.csv |

Control PC |

\OUTPUT (if exists) |

|

Measurement Condition State |

.sta |

E4991B |

\STATE (if exists) |

|

Temperature Change Compensation |

.cpn |

E4991B |

\COMPEN (if exists) |

This sample program allows you to perform measurement under up to 3 different state conditions at each temperature point. At each temperature point, measurement is performed while reproducing measurement conditions by loading the specified state file (.sta). Prior to measurement, therefore, set measurement conditions and save the state file after the execution of calibration/compensation.

Set the measurement conditions of the E4991B.

Execute calibration/compensation on the instrument.

Save the state file (.sta) in the instrument. If you want to perform measurement under other conditions, repeat steps 1 through 3.

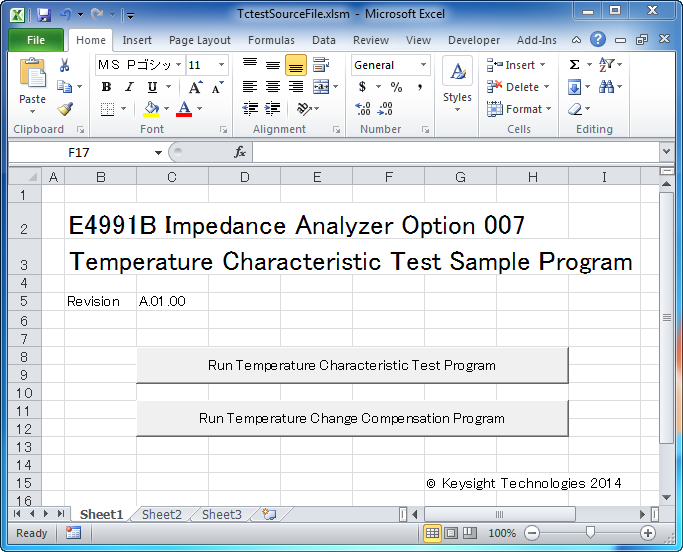

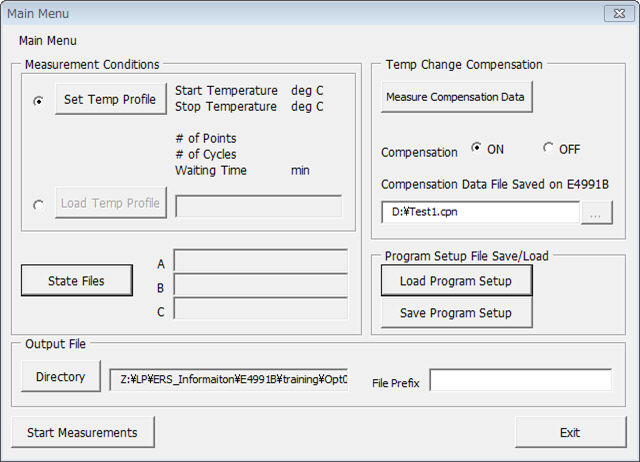

Launch TcTest.xlsm in Excel. The below screen appears. Select Run Temperature Characteristic Test Program option.

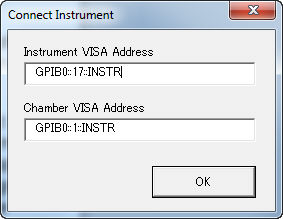

After the title window, “Connect Instrument” dialog is launched. Enter the VISA address of the E4991B and chamber. If the program runs on the E4991B, connection with the firmware is automatically established.

Set the measurement conditions and temperature conditions. You can set one of the following temperature changes (profiles):

Stepwise temperature change

Arbitrary temperature change

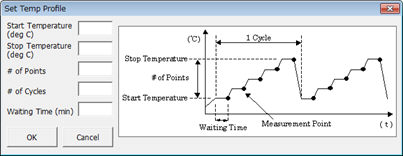

To change temperature stepwise, click Set Temp Profile button and set the following temperature change parameters to specify a temperature change pattern.

|

Parameter name |

Description |

|

Start Temperature |

Temperature of the first measurement point. |

|

Stop Temperature |

Temperature of the last measurement point. |

|

# of Points |

Number of measurement temperature points. |

|

# of Cycles |

Number of temperature change repetitions from Start Temperature to Stop Temperature. |

|

Waiting Time |

Waiting time from when each measurement temperature reached as specified to when the measurement is started. |

Although the figure above shows a temperature change pattern from the lowest temperature to the highest temperature, you can set the start temperature to the highest temperate and thestop temperature to the lowest temperature.

Unit, resolution, and limit values of each parameter

|

Parameter name |

Unit |

Resolution |

Maximum value |

Minimum value |

|

Start Temperature |

°C |

0.1 |

150 |

-55 |

|

Stop Temperature |

°C |

0.1 |

150 |

-55 |

|

# of Points |

- |

1 |

25 |

1 |

|

# of Cycles |

- |

1 |

9 |

1 |

|

Waiting Time |

Minute |

1 |

999 |

1 |

To change temperature arbitrarily, you have to load a temperature profile file. Click the Load Temp Profile button in the Main Menu.

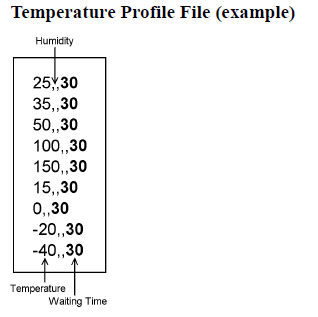

To change measurement temperature arbitrarily, you need to create a temperature profile file (measurement temperature state file). The extension should be ".TPR."

Create files on your external PC. In the temperature profile file, each measurement temperature (and humidity) and waiting time after the specified temperature (humidity) reaches as specified are written in the order of:

{temperature},{humidity},{waiting time} separated with a comma (,). Each temperature point is separated with a line feed.

No space is required between a value and a comma(,). When you do not specify humidity, place no space between commas. Always enter temperatures and waiting times.

Unit, resolution, and limit values of temperature profile data

|

Parameter name |

Unit |

Resolution |

Maximum value |

Minimum value |

|

Temperature |

°C |

0.1 |

150 |

-55 |

|

Humidity |

% |

0.1 |

99 |

0 |

|

Waiting Time |

Minute |

1 |

999 |

1 |

To set the state file, click the State Files button on the Main Menu. On the State Files screen, enter the absolute path of the desired state files you saved in advance, followed by the OK button. You can specify up to 3 files each for A to C. Specify at least one file.

When you perform temperature compensation, you need to acquire temperature compensation data according to the following procedure before measuring the DUT. If you already have compensation data file (*.cpn), this operation can be skipped.

If the DC bias feature (option) is provided, turn it off while acquiring temperature compensation data.

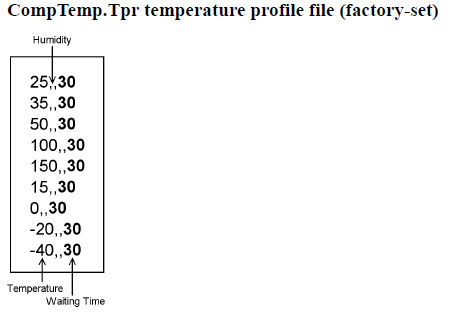

Specify measurement temperature settings using the following temperature profile file. The only valid temperature profile file name is CompTemp.Tpr., and it needs to be located in the same directory as Tctest.xlsm. Figure below shows the temperature profile file provided at the factory. You need to acquire temperature compensation data for all measurement temperatures, making any changes as necessary.

D:\Tctest\CompTemp.Tpr

The only valid temperature profile file name when acquiring temperature compensation is D:\Tctest\CompTemp.Tpr.

In the temperature profile file, each temperature (and humidity) at which you want to acquire compensation data and waiting time after the specified temperature (humidity) reached as specified are written in the order of:

{temperature},{humidity},{waiting time} separated with a comma (,). Each temperature point is separated with a line feed.

Make sure that the temperature of the E4991B and the end of the measurement cable is within 18°C to 28°C and execute the open/short/load calibration at the end of the measurement cable (7-mm port) in the fixed frequency and fixed power point mode.

Keep the measurement cable in the same position as it was when calibration was performed.

Click the Measure Compensation Data button on the Main Menu.

Click the Compensation Data File button.

On the Compensation Data File screen, enter the compensation data file name and click OK.

Click Start Measurement button to start temperature compensation data measurement.

When the Open Temperature Change Compensation Data screen appears, connect the heat-resistant open standard attached to Option 007 and then click the Meas button to start the open measurement.

When measurements at all temperature points are completed, "Open: Done. Please press Next" message appears. Click the Next button.

When the Short Temperature Change Compensation Data screen appears, connect the heat-resistant short standard attached to Option 007 and then click the Meas button to start the short measurement.

When measurements at all temperature points are completed, "Short: Done. Please press Done" message appears. Click the Done button.

Select ON radio button for Compensation in Temp Change Compensation.

Specify your desired compensation data saved in acquiring temperature compensation. The compensation data file should be located in the E4991B. Hence, the file path should be on the instrument.

Click... button in Temp Change Compensation is grayed out when this software is located in an external PC. Click... button is available only when this software is located in the E4991B.

You can also save and load the setting of Measurement Conditions and Temp Change Compensation as a Program Setup file (.hed file).

Click the Load Program Setup button to display the Open File dialog box. Select your desired file and click OK button.

Click the Save Program Setup button to display the Save File dialog box. Enter a file name and click the OK button.

Click Directory button in Output File on the Main Menu to display the Browse For Folder dialog box. Specify an output directory and click the OK button.

Enter a desired prefix for output files in Output File.

Measurement results are saved in files whose name is automatically generated with the prefix you specified. The files are located under the directory you specified.

For example, if you specify an output file name as "test," the measurement result of trace 2 under the measurement conditions in state file B is saved under the name "test_B2.csv"

When you have entered all the following conditions, you can start measurement.

Temperature profile condition

State file

Temperature compensation data setting: when using temperature compensation data

On/off of using temperature compensation data

Output file

Click the Start Measurements button on the Main Menu to start measurement. Measurement results are saved in Output files.

When the measurement is complete, the temperature chamber is set to the initial temperature (at the start of measurement).

You can execute temperature compensation for your manual measurement result using Temperature Change Compensation Program.

This macro assumes that temperature compensation data was acquired before it is used.

Functions that Temperature Change Compensation Program provides are equivalent to the softkeys under Cal > Temp Compen (For Option 007).

Execute measurement

Set the trigger setting of the E4991B to Hold (sweep stop).

Load TcTest.xlsm and run Temperature Change Compensation Program.

Specify the absolute path to the compensation data file.

Click the Load Compensation Data button on the Main Menu to display the Load Compensation Data screen. Click the browse button.

Select your desired file and click the OK button.

Enter the temperature when executing measurement (at the set temperature of the temperature chamber).

Click the Compensation button on the Main Menu to apply the temperature compensation.