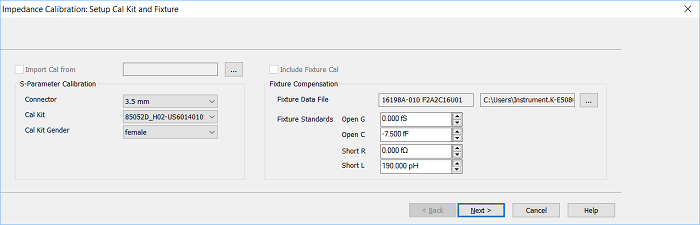

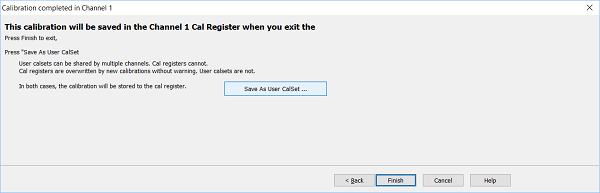

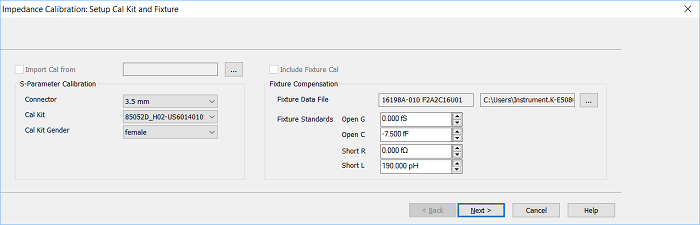

Import Cal from Choose

Cal Sets file from "..." if you have a Cal Set

with 85052DH02.

Check: The selected Cal Set file is used for S-Parameter

calibration. The selected calibration kit in S-Parameter

Calibration is ignored. If you set a STD Class Cal

Set (Cal Set was taken in STD class with 85052DH), only S-parameter

calibration can be skipped. Uncheck: Execute S-Parameter calibration and Fixture

Compensation from scratch.

Import Fixture Cal from

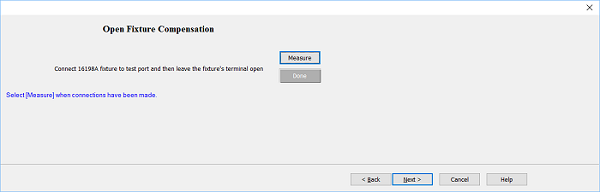

Check: The open/short fixture compensations are

also skipped. The fixture data file name and fixture standard

data are displayed and the open/short fixture compensations

data in the Cal Set file is used.

When you use a Cal Set file with ZA class, importing a Cal

Set file from Cal >

Cal Sets & Cal Kits

> Cal Sets.... is

the equivalent operation Uncheck: Retake a Fixture Compensation only. S-Parameter

calibration data is used from the selected Cal Set file. If

selected Cal Set file is STD class, this cannot be checked.

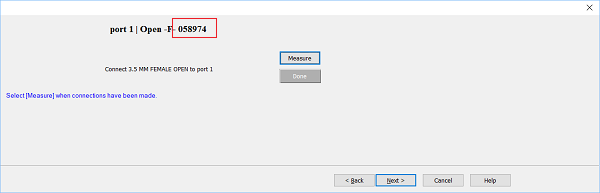

S-Parameter Calibration

Connector Only

3.5 mm can be selected for the19198A.

Cal Kit Select

the calibration data which you imported at Cal Kit diaglog box.

Cal Kit Gender Only

female can be selected for the 19198A.

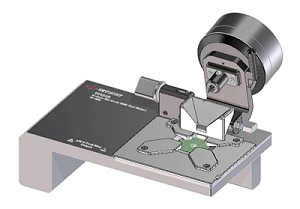

Fixture Compensation

Fixture Data File Display

the imported fixture calibration data file. Import the fixture

calibration data file by clicking "...".

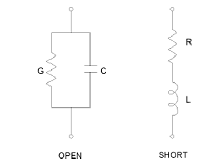

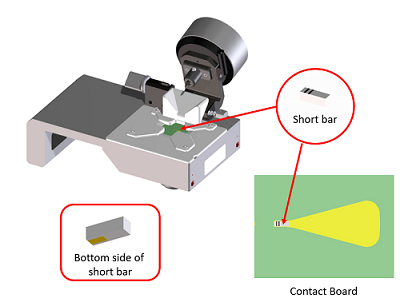

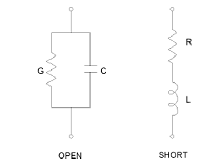

Fixture Standards

Define the values for open/short standard values. Open Conductance

(G), Open Capacitance (C), Shot Inductance (L) and Shot resistance

(R). See the procedure above for the 16198A.

Next > is not activated

in the following conditions.

|