Getting Started

|

|

-

N7841A calibration application versions E.04.02 and greater require a minimum version of firmware to be installed in the FieldFox to successfully run tests and adjustments. Refer to the Firmware Requirements section for more information.

-

Some FieldFox model and option combinations will require the installation of the CFG Option in order to complete tests. All adjustments will require the CFG Option. Refer to the CFG Option section for more information.

|

Before You Start

Installing Over Previous Versions

Please see the Readme.txt of TME for information on the compatibility of this

package with previous versions of the application and the Test Management

Environment (TME).

|

|

TME applications E.01.00 and later cannot be installed over older TME

applications (A.xx, C.xx, or D.xx) or on top of TME versions prior to

E.01.00. You must remove TME and all applications from the PC before installing

the latest TME and this application.

Please see the TME help, Getting Started, Installation section for details

of how to remove pre-E.01.00 versions of TME and its applications.

|

Separation of TME from Applications

Keysight TME is no longer packaged and installed with

TME applications. TME must be installed separately. Once TME is installed

on the target PC, the applications can then be installed.

Please see the TME help system and Readme for information

on installing the Keysight Test Management Environment.

System Requirements

Please see the Readme.txt for minimum system requirements to run this

application.

Installation Steps

There are two ways to install TME and its applications:

-

Network

Installations — Equipment and test data information is stored in a

central location (the TME Server). This data is shared among a set of

TME Clients. Multiple test stations can then have access to this central

information.

-

Local Installations — Everything is installed on one PC.

Installation

Network Installation

In a network installation, order information is stored centrally and

can be accessed by any TME client in the network. This allows you to combine

data from tests that were run on multiple stations into a single report.

Equipment data and order information are also accessible from any station.

To set up a new TME network, please see the instructions in the TME

help system.

|

|

-

The

installation of the application network data must take place on the same

PC that installed the TME network data.

-

If TME is setup as a network installation, the application will automatically

be setup as a network on that machine when the installation is executed.

The application server must be installed before any clients can be installed.

-

TME client must also be installed on all machines intending to run this

application as clients of the network.

|

To install an application on a network follow the following steps:

-

Find the PC where the TME network was installed (shows

“TME Server” in Programs & Features).

-

Run Setup.exe for the application on that PC. This will

install all networked components for that application.

-

Install application clients:

Or

\\FileServer\Test

Management Environment\Install\(AppName)\(AppName)ClientSetup.exe

|

|

The

client setup must be run from this location. It should not be moved or

renamed.

|

Local Installation

TME must be installed on the target PC before the application

installation can occur.

On a local installation, all application data is stored

on the target PC. Once TME has been installed as a local installation,

the application installation will automatically install locally when executed.

Order information, test results, and equipment data will not be shared

with other users.

Uninstallation

|

|

If you uninstall TME completely or uninstall any TME application,

you will lose the data associated with those applications. Create any

reports needed and save them as PDF files before you uninstall that product.

|

-

To uninstall previous versions of TME, please see Installing

over Previous Versions.

-

To uninstall TME or any TME application, select that package

from Programs & Features.

Uninstall of Network Install

To uninstall an application client, select that package from Programs & Features, and click Remove.

|

|

Data

will not be lost if only a client is uninstalled. Other clients will still

have access to the data in the network.

|

To uninstall an application server:

-

Follow the directions above to uninstall all application

clients.

-

Once all application clients have been uninstalled,

uninstall the application server from the PC where the server installation

was performed.

-

Select the application server from Programs & Features, and click Remove.

Uninstall of Local Install

To uninstall an application local installation, select that package

from Programs & Features, and click Remove.

N7841A Application Installation

|

|

-

N7841A calibration application versions E.04.02 and greater require a minimum version of firmware to be installed in the FieldFox to successfully run tests and adjustments. Refer to the Firmware Requirements section for more information.

-

Some FieldFox model and option combinations will require the installation of the CFG Option in order to complete tests. All adjustments will require the CFG Option. Refer to the CFG Option section for more information.

|

The N7841A test application must be installed on a PC with a LAN port. The LAN connection for the PC is required because the N7841A test application

communicates with the UUT via LAN. (This

does not mean the N7800A installation must be a network installation;

a local installation is acceptable.)

The N7841A test application communicates with the test equipment via

GPIB. The LAN connection for

the FieldFox analyzer is required because the UUT is not equipped with a

GPIB interface.

Check the following PC configuration:

File and Printer Sharing should be enabled on the PC running TME. On the PC:

- Select Start > Control Panel > Windows

Firewall and select the Exceptions tab.

- Check the File and Printer

Sharing box.

- Click OK.

|

|

If the PC is not configured properly, an error may be generated with DrivingDataFiles

in the filename path.

|

Connecting the FieldFox Analyzer to a LAN and Configuring the IP Address

The calibration software communicates with the FieldFox through LAN. Therefore,

the FieldFox needs to be configured for network activity.

|

|

The procedures below can be made during the UUT warm-up.

|

-

Connect the LAN cable from the LAN connector on

the side of the FieldFox to an available connector on a local area network or

directly to the TME PC. If the FieldFox is connected to a local area network, follow Step 2 below to configure the FieldFox to obtain the IP address

via DHCP. If connected directly to the TME PC, set the FieldFox for

a static IP address. A "cross over" LAN cable is not required

when making a direct connection between the FieldFox and the TME PC.

-

To configure the FieldFox to obtain an IP address

via DHCP:

-

Press System 7 > System

Configuration > MORE > LAN soft keys; press

the down arrow button to scroll down to the Obtain IP line.

-

If the value needs

to be changed, press the Edit soft key. Press the Obtain IP soft key to underline DHCP. Press Done Edit.

-

Scroll down to

the Apply Settings line.

-

Press the Edit > Apply Settings soft keys. A box should briefly

appear toward the lower right-hand corner of the display indicating File Saved:

\UserData\LanConfig.reg.

The underline in the Apply Settings

soft key should indicate PowerUp after a few seconds. If not, repeat this step. Press Done.

-

There should now be a

value for Current IP Address. If there is no value displayed,

then cycle power on the

FieldFox (hold on/off button for four seconds to turn off). This will allow

the DHCP server to assign an IP address.

-

To configure the FieldFox to use a static IP address:

-

Go to https://www.keysight.com/us/en/lib/resources/technical-specifications/telnet-communication-to-the-fieldfox-over-lan-2100789.html . Follow the

instructions for the Direct Connection option. It is recommended

to open a telnet connection between the PC and FieldFox to confirm that the

connection is established.

-

Press System

7 > System Configuration > MORE > LAN.

Record the current IP address.

Enter IP Address in TME

Follow the steps below to enter the FieldFox IP address in TME.

-

When creating a new order in TME, select the

model number and click the Model Info…

button.

-

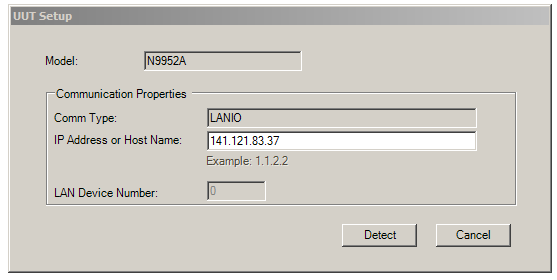

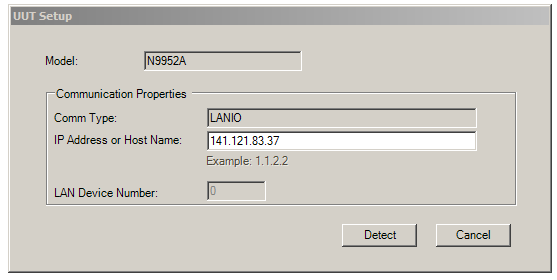

In the UUT Setup

dialog box (example below), type in the IP address of the FieldFox analyzer and then click on the Detect

button.

-

After you click on the Detect

button, the information from the UUT will be displayed. After reviewing

the information and entering the desired data, press the Done

button.

-

Press Save to complete the creation of

the order.

|

|

To change the IP address for

an order after it has been saved, select File > Edit Order.... at the top of the window. Then click the Model Info....

button.

|

Connecting GPIB Test Instruments

This section describes the preparation of the instruments

used by the test software at a given test station. The test software does

not check instruments for proper operation on the GPIB bus before attempting

to perform tests.

All test equipment controlled by GPIB should be connected to the GPIB connector of the controller PC (typically GPIB0).

The typical GPIB address configuration for a test station is:

|

Signal Generator

|

19

|

|

Power Meter

|

13

|

|

Frequency

Counter

|

3

|

|

Source

|

19

|

|

Network Analyzer

|

16

|

|

DVM

|

22

|

|

Function Generator

|

10

|

|

Oscilloscope

|

4

|

It is recommended that the operator follow the steps below to manually

check for proper connection of the GPIB devices before performing tests

on a newly connected test station.

-

Note the GPIB address of each

instrument associated with the test station/test plan defined earlier.

-

Connect a power cord to each

instrument, and then connect each instrument to the computer serving as

the GPIB controller.

-

Power up all the instruments

on the GPIB bus.

-

Check each GPIB instrument for proper communication

over the bus and the required . Follow the

process described in "Checking GPIB Bus Devices" below.

Checking GPIB instruments

|

|

When checking the basic operation of each instrument or when checking

for detectable options on a given instrument, you may need to look up

the actual command for retrieving the identification string before performing

these steps.

|

-

Start the Keysight Connection Expert from the task bar or access it through Start > All Programs > Keysight Connection Expert.

-

Check for all expected GPIB devices. Verify that all expected GPIB devices are shown in the left window. If a device is missing, correct the problem and re-scan for connected instruments.

-

Check for basic operation of each GPIB device:

|

|

If an instrument does not support SCPI, refer to the user guide for

the product to learn more about checking the basic operation of its GPIB.

|

-

Select a GPIB device.

-

Select the Interactive

I/O from the right window.

-

The command window should be pre-populated with the *IDN? query. You can also select from the Commands > drop-down menu, or simply type *IDN? in the command window.

-

Select Send & Read.

-

Verify that the expected model number is contained

in the response text string.

-

Check for on a given device:

|

|

This does not work with the power meter.

|

-

Select a GPIB device to highlight it.

-

Select the Interactive

I/O from the right window.

-

Type *OPT?

in the command window.

-

Select Send & Read.

Warm-up Procedures

Ambient temperature recommended during adjustments and

tests: 20° to 26° C.

To display the temperature sensor readings on the FieldFox, press System (7) > Service Diagnostics > Internal Temperatures

Internal temperature range required for adjustments and recommended for tests:

RF1 and RF2 sensors are located on the RF PCA.

SB1 and SB2 sensors are located on the System Board PCA.

|

Model

|

Sensor

|

Temperature Range:

Firmware < A.09.00

|

Temperature Range:

Firmware ≥ A.09.00

|

|

N9923A1

|

SB2

|

43 to 55° C

|

48 to 58° C

|

|

N9912A

|

RF2, SB22

|

40 to 50° C

|

45 to 55° C

|

|

N991xA/N992xA/N993xA

|

RF2, SB22

|

43 to 55° C

|

48 to 60° C

|

|

N995xA/N996xA

|

RF2, SB22

|

N/A

|

48 to 62° C

|

|

1. Temperature range for Phaselock Accelerator Adjustment is 43° C to 53° C.

2. SB2 is only checked in the Frequency Accuracy Adjustment.

|

Typical stabilization time: 60 to 90 minutes

When positioned with an open kick stand, the internal temperature of the unit will typically

rise above ambient temperature by the following degrees:

- N9912A — 23° C

- N9923A — 29° C

-

All other — 30° C

The

temperature rise will depend on operating mode and battery charge level.

The UUT must remain in a consistent thermal environment

during warm-up, adjustments, and testing. This includes ambient air

temperature, circulation of ambient air on the unit, and physical

position of the unit (kick stand, etc). The UUT should have a battery installed and be continuously connected to external power during

warm-up, adjustment, and testing.

Warm-up Procedure

This procedure assumes the UUT is off.

-

Connect external power to the UUT, turn it on, and preset it (Preset

> Preset).

-

Position the UUT in the upright position using the built-in kick stand.

-

Allow the internal temperature to stabilize before performing any tests (less than a one

degree change in ten minutes). Typical stabilization time: 60 to 90 minutes.

-

Before performing adjustments, make sure the UUT is stabilized in the required temperature range (see above).

When the stabilized temperature is not within the required range:

-

If the temperature is too low, collapse the kick stand and

lay the UUT on its back. This should raise the internal temperature about

four degrees. An alternative is to place insulating material (foam, etc.)

against the back of the UUT under the kick stand.

-

If the temperature is too high, position a small fan to

circulate air between the kick stand and the back of the UUT. This should lower

the internal temperature about five degrees depending on the volume of

air flow.

-

Changing the display brightness will affect heating within the

UUT. Set the display to 100% brightness to dissipate maximum power in the

UUT.

-

Allow the internal temperature of the UUT to stabilize again. Confirm that the UUT is in the required temperature range before beginning

adjustments or tests.

ESD Precautions

Protection against ESD (electrostatic discharge) is essential

while connecting, inspecting, or cleaning connectors attached to a static-sensitive

circuit (such as those found in test sets). Static electricity can build

up in your body and can easily damage sensitive internal circuit elements

when discharged. Static discharges too small to be felt can cause permanent

damage. Devices such as calibration components and units under test (UUTs)

can also carry an electrostatic charge. To prevent damage to the test

set, components and devices:

-

Always

wear a grounded wrist strap having a 1 million Ohm resistor in series

with it when handling components and devices or when making connections

to the test set.

-

Always

use a grounded antistatic mat in front of your test equipment.

-

Always wear

a heel strap when working in an area with a conductive floor. If you are

uncertain about the conductivity of your floor, wear a heel strap.