Other topics about Calibration

The calibration data of open/short/load/low-loss capacitor is measured according to the following procedure.

Perform calibration as follows:

Calibration consists of three calibration data acquisition procedures: OPEN, SHORT, and LOAD, and you must obtain all three types of calibration data when performing the calibration. LOW LOSS C is an optional calibration. It is not possible to turn ON or OFF each type of calibration data independently during your measurement.

Press Cal to display the Calibration Menu.

Select calibration (compensation) data acquisition points in accordance with Selecting Calibration/Compensation Data Points.

Press Calibration to display the Calibration Menu.

If required, set user-defined standard values in accordance with Defining Standard Values for User Calibration.

Press Execute Cal to display the Calibration Execution Menu.

Connect the OPEN standard to the port (plane) where you want to perform the calibration.

Press Open to start OPEN calibration data measurement. When OPEN calibration data measurement is completed, the softkey label changes to Open √.

Remove the OPEN standard from the port. Then, connect the SHORT standard to the port.

Press Short to start SHORT calibration data measurement. When the SHORT calibration data measurement is completed, the softkey label changes to Short √.

Remove the SHORT standard from the port. Then, connect the LOAD standard to the port.

Press Load to start LOAD calibration data measurement. When LOAD calibration data measurement is completed, the softkey label changes to Load √.

Remove the LOAD standard from the port. Then, connect the LOW LOSS C standard to the port. This is an optional calibration measurement.

Press Low Loss C (Optional) to start LOW LOSS C calibration data measurement. When LOW LOSS C calibration data measurement is completed, the softkey label changes to Low Loss C (Optional) √.

Press Done to start calculating the calibration coefficient from the measured OPEN, SHORT, LOAD and LOW LOSS C standard data. The coefficient is automatically saved to the internal memory.

During the calibration data measurement, the message Sweeping... is displayed in the instrument state area at the bottom-left of the screen.

Press Cancel to cancel the user calibration process. If the user calibration process is canceled, the previously obtained data can be used as the available user calibration coefficient.

The user calibration function is automatically turned on after completing user calibration data measurement. However, you can turn this function on or off as required.

Press Cal > Calibration to display the User Calibration Menu.

Press Correction > ON|OFF to make the user calibration available (ON) or not available (OFF) for measurement.

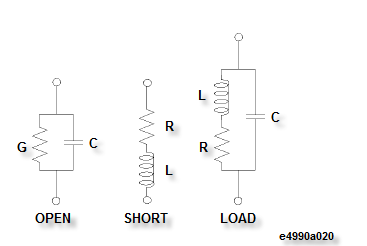

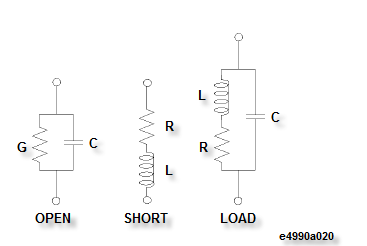

You can define standard values of OPEN, SHORT, and LOAD for user calibration. Figure below shows the circuit models of the user calibration kit for the Keysight E4991B. In addition, the offset electrical delay from the calibration plane to the circuit model can be defined foe each calibration's standard.

Each calibration’s standard value can be confirmed and changed as follows:

Press the Cal > Calibration > Define Value to display the Calibration Data Definition Menu.

Select one of the calibration data definition keys, Open Conduct (G), Open Cap (C), Open Offset Delay,Short Resist (R), Short Induct (L), Short Offset Delay, Load Resist (R), Load Induct (L), Load Cap (C) or Load Offset Delay, to confirm or set the calibration data definition.

Enter the desired value to specify the calibration data definition.