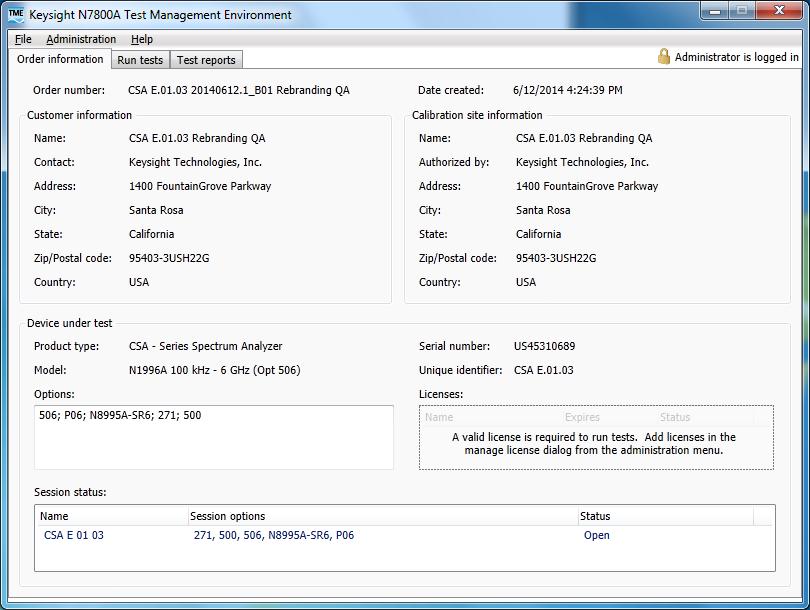

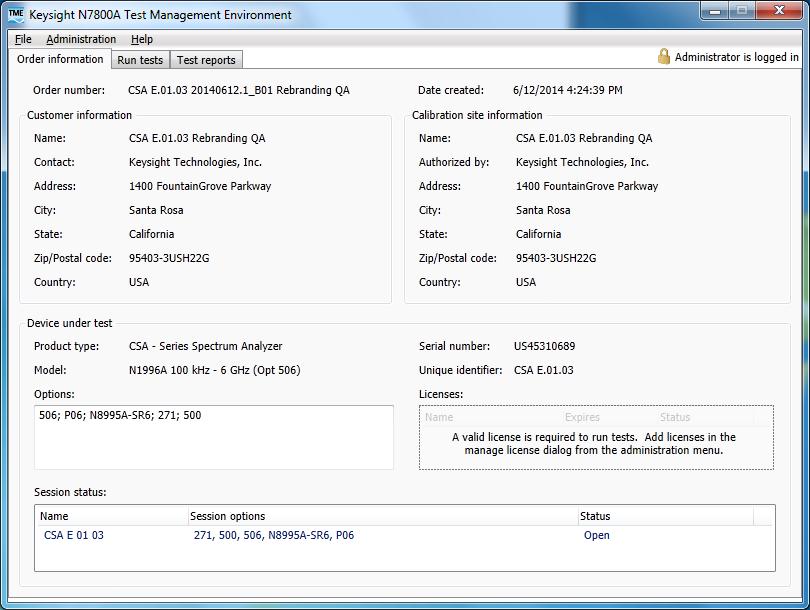

Using TME — Overview

The Test Management Environment uses a tab-based graphical

user interface with extra functionality via menu driven tasks. This topic provides a basic overview of TME functionality.

Initially the tabs that are selectable are:

|

Order Information

|

-

For information only.

-

Review information about an order, such as the order number, date, product, model, and serial number.

|

| |

|

|

Test

Reports

|

- View test data and combine into reports

|

|

It

is necessary to enter valid license information in order to access the

full functionality of the Test Management Environment. For more information

on entering license information, see the Licenses

section.

|

|

|

Run

Tests

|

|

Drop Down Menus

|

File

|

|

| |

|

|

Administration

|

-

Allows a system administrator to set up test equipment and manage test

data and licenses. As of E.03.75 release, the Administrative Login is now optional. The default, as shipped by TME, is that the Administrative Login is disabled. (Refer to Enable Administration Login in the Option Panel topic.) Once enabled, an administrator’s password is necessary to access most

of these menu items.

|

| |

|

|

Help

|

|

TME User Interface

Administrator/Operator

Distinction

The TME product is designed to have two distinct user

groups, Administrators and Operators. The

Administrator is able to define test stations, add, change, and remove

information about test equipment and test stations, including equipment

and calibration standards control, data management, and system setup. The

Operator is the person actually executing the tests and creating the data

reports using the pre-defined information supplied by the Administrator.

Order/Session Concept

Before running any tests within TME, a new order is created.

This allows product-related data to be grouped together and easily retrieved.

Within each order there is also the concept of sessions. A session is

a subset of data within the order which is used to generate reports. There

can be any number of sessions for a particular order. An example

of possible sessions may be: "Product As Received", "Product

Repair Testing" and "Product As Shipped". These sessions

could be used to produce three separate reports.

Using sessions

Most orders may only require a single session. By default,

the first session created within an order is named "As Received"

and the second session "As Shipped". Both of these names are default

suggestions and may be changed to any user preference. If a single

report is required for all testing carried out on a particular product,

only one session should be used. Report data can only be gathered from

a single session at a time. Different test run sequences from different

stations are created at different times and may be gathered to create a single

report, provided they are part of the same order session. Session-based reports are generated from saved session

data and can be customized to include the desired group of test data from

a choice of all test runs within the session.

ETE and Environmental Information

External Test Equipment (ETE) is the equipment required

to test any given product. Most of the products supported by TME

require extensive ETE to allow full testing to be carried out. The

ETE is added to TME by the Administrator and is grouped by Test Station. A

single Test Station can be used for all ETE if the ETE tends to be shared

among several locations or if ETE is rack mounted and usually kept in

a fixed location. Separate Test Stations may be added to reflect this. Once

the Administrator has entered ETE into a Test Station, the Operator can

then select from the available choices when running tests. ETE is an important

part of calibration traceability and it is important that all required

calibration information is entered correctly.

Environmental information can be set to default values

by the Administrator if they are not prone to variation, or entered/updated

by the Operator to reflect current conditions. The temperature and humidity

values can be automatically updated if you use the environmental sensor described here.

The values entered can sometimes affect the specifications

tested to and are included on any reports generated.

|

|

Only

one operator can use a test station at one time.

|

Miscellaneous Information

Warmup Time

Allow sufficient warmup time for the test equipment and instrument under

test (also referred to as unit under test, UUT). Refer to individual operating

and service manuals for warmup specifications.

Failure to meet specifications

If the instrument does not meet one or more of the specifications during

testing, check the test setup for proper configuration. Also check the condition

of all connectors and ensure all connections are tight. Repeat the failed tests again. If

the results are still unsatisfactory, complete any remaining tests and

refer to the troubleshooting information in the service guide to correct

the problem.

Abnormal indications during adjustment

If the indications received during an adjustment do not agree with the

normal conditions given in the adjustment procedures, a fault exists in

the instrument. The fault should be repaired before proceeding with any

further adjustments. Refer to the troubleshooting and repair information

in the service guide.