Cleaning Optical Connections

The fiber-optic input and output connectors on many Keysight Technologies instruments employ

- Lever adapters (for example on an N1090-series DCA-M).

- Screw-on universal adapters (for example on an 86105C), or

These adapters, when removed, have no fiber-optic parts and can be cleaned using the procedure in this topic.

If flammable fluids are used to clean connectors, the fluid shall not be placed on the instrument during use or when connected to mains voltage. Cleaning the connectors shall take place in ventilated area to allow fluid vapors to dissipate, and reduce the risk of fire.

Cotton swabs can be used as long as no cotton fibers remain after cleaning. The foam swabs listed in this section's introduction are small enough to fit into adapters. Although foam swabs can leave filmy deposits, these deposits are very thin, and the risk of other contamination buildup on the inside of adapters greatly outweighs the risk of contamination by foam swabs.

- To remove a screw-on universal adapter from a module, turn the adapter counter clockwise.

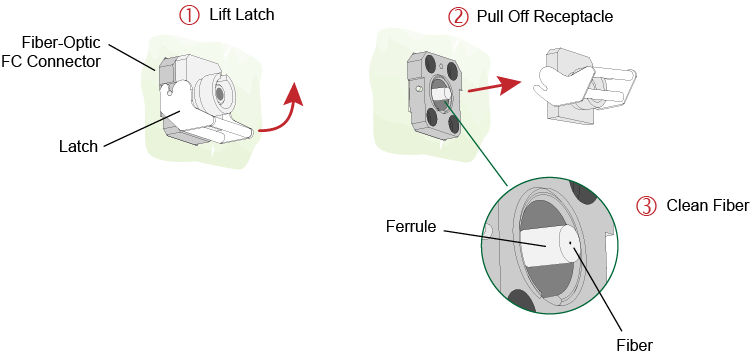

- Lift the receptacle latch as shown in the following picture.

- Carefully pull off the receptacle without touching the ferrule or fiber end.

- Clean the adapter with the foam swab.

- Dry the inside of the adapter with a clean, dry, foam swab.

- Blow through the adapter using filtered, dry, compressed air. Nitrogen gas or compressed dust remover can also be used.

Do not shake, tip, or invert compressed air canisters, because this releases particles in the can into the air. Refer to instructions provided on the compressed air canister.