3. Work at ESD Workstation

Failure to follow ESD guidelines can result in severe damage to the product. In some cases, an input connector is an integral part of the electrical sampler device. Therefore, by using improper ESD workstations, you risk expensive instrument repairs.

Static-Safe Workstation

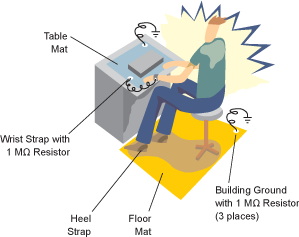

Electrostatic discharge (ESD) can damage or destroy electronic components. All work on instruments and electronic components should be performed at a static-safe workstation as shown in the following figure . The static-safe workstation uses two types of ESD protection:

The following suggestions may reduce ESD damage that occurs during testing and servicing operations.

- Personnel should be grounded with a resistor-isolated wrist strap.

- Be sure all instruments are properly earth-grounded to prevent a buildup of static charge.

These techniques for a static-safe workstation should not be used when working on circuitry with a voltage potential greater than 30V rms, 42.4V peak, or 60V DC volts.

Only the table-mat and wrist-strap combination provides adequate ESD protection when used alone. To ensure your safety, the static-safe accessories must provide at least 1 MΩ of isolation from ground. Purchase acceptable ESD accessories from your local supplier.

Electrical channel input circuits and the trigger input circuit can be damaged by electrostatic discharge (ESD). Therefore, avoid applying static discharges to the front-panel input connectors. Prior to connecting any coaxial cable to the connectors, momentarily short the center and outer conductors of the cable together. Avoid touching the front-panel input connectors without first touching the frame of the instrument. Be sure that the instrument is properly earth-grounded to prevent buildup of static charge. Wear a wrist-strap or heel-strap.

Grounding Receptacle

If the instrument has a grounding receptacle, you can plug the wrist strap into the grounding receptacle. The front-panel grounding receptacle that is shown in the following picture.

Daily ESD Self Check

Perform the following steps as part of your daily ESD self check.

- Visually check your work area to see that there are no static-generating materials, insulating work surfaces, or static-generating tools.

- Clear your work area of static charge generators for a distance of at least 1 meter from ESD sensitive items.

- Visually check that the ground wiring to the workstation has not been disconnected or damaged.

- If applicable, make certain that your work station air ionizer is activated and correctly positioned.

- Make sure that there are no static generators inside conductive containers with ESD sensitive items.

- Visually check that all ESD sensitive parts, assemblies, or products are completely inside closed conductive containers.

- Make sure that all shielding containers have an approved static attention label on the outside.

- Make sure that all cleaners, solvents, coatings, and sprays used at your workstation are types approved by your ESD Coordinator.

- Put on wrist strap and conductive footwear, and any special garments which are required in your job.

- Don’t allow anyone who is not grounded closer than 1 meter to your static safe area.