External Millimeter-Wave Module Configuration

This feature, when used with the N526xA test sets and external mmWave

Modules, extends the frequency coverage of your PNA. The N5251A

broadband system is also configured using the Millimeter

Module Configuration dialog.

In this topic:

See Also

Other

IF Access Topics

Note: In the PNA

user interface and in this help file, the N526xA Millimeter Head Controller

is referred to as a test set.

The test head modules are referred to as mmWave

modules.

CAUTION: Turn OFF

test set power before connecting or disconnecting the DC cable to the

mmWave modules.

Features

The following Applications

are supported:

The following configurations are supported:

PNA-X or N522xA with options Opt

020 works with N5260A, N5261A, and N5262A Test Sets.

When using the N5262A test set, a 2-port PNA-X or

N522xA requires Opt

551.

Broadband - single

sweep from 10 MHz to 110 GHz.

Banded - frequency

coverage divided into bands.

Limitations

Power Settings

When using mmWave modules with an N5260A test set, the PNA can

NOT control the power level into your DUT. Your mmWave modules may

have a variable attenuator on them. When

used with an N5261A or N5262A, after performing a Source Power Cal,

then the PNA power settings may be used to control the power into

the DUT. See Leveled

Power Capabilities.

To protect your mmWave modules from damage, the settings

on the Millimeter Module Configuration dialog can ONLY be changed

manually. They can NOT be reset or changed by performing a Preset,

by recalling an Instrument State, or from a remote program.

ONLY the Applications

listed above are supported.

Broadband and

Banded mmWave Measurements

Broadband refers to mmWave configurations with a frequency range of

10 MHz to 110 GHz. This configuration spans the entire frequency range

in a single sweep.

Banded refers to any configuration that is not a broadband configuration

and is waveguide based. Frequency extenders cover frequency ranges from

50 GHz to 1.1 THz. The supported solutions can be configured for different

frequency bands with or without a test set controller depending on the

measurements required and the frequency extenders being used.

The following table shows the waveguide designation equivalents.

| MIL-DTL-85/3C |

IEEE Std 1785.1 |

Frequency Range |

| WR-15 |

WM-3759 |

50

GHz to 75 GHz |

| WR-12 |

WM-3099 |

60

GHz to 90 GHz |

| WR-10 |

WM-2540 |

75

GHz to 110 GHz |

| WR-08 |

WM-2032 |

90

GHz to 140 GHz |

| WR-06 |

WM-1651 |

110

GHz to 170 GHz |

| WR-05 |

WM-1295 |

140

GHz to 220 GHz |

| WR-04 |

WM-1092 |

170

GHz to 260 GHz |

| WR-03 |

WM-864 |

220

GHz to 330 GHz |

| WR-02 |

WM-570 |

330

GHz to 500 GHz |

| WR-1.5 |

WM-380 |

500

GHz to 750 GHz |

| WR-1.0 |

WM-250 |

750

GHz to 1.1 THz |

| Reference:

IEEE Standard for Rectangular Metallic Waveguides and their interfaces

for frequencies of 110 GHz and above - Part 1: Frequency Bands

and Waveguide Dimensions. |

PNA-X Notes

CAUTION:

Connect a 10 dB attenuator to the N5260A LO input from the LO

Output. Otherwise, damage will occur to the N5260A test set.

The PNA-X or N522xA rear panel IF

Inputs use 5 SMA connectors. Previous PNA models use BNC connectors.

Adapters may be required.

Beginning with A.09.00, Frequency Offset and SMC Measurements

are supported when using mmWave modules. Learn

more.

Beginning

with A.10.45, Spectrum Analyzer Measurements are supported when using

mmWave modules. Learn

more.

How to Configure

Millimeter-Wave Modules |

Using

front-panel

hardkey [softkey] buttons |

Using

Menus |

Press system then [Configure] then [Millimeter

Module] |

Click Utility then System then Configure then Millimeter

Module Config |

There are NO programming commands

to configure mmWave modules and test set. |

Millimeter

Module Configuration dialog box help |

|

Note: To

protect your mmWave modules from damage, settings on this dialog

can ONLY be changed manually or with a remote program. They

can NOT be reset or changed by performing a Preset, or by recalling

an Instrument State.

Available Configurations

Lists the Standard PNA configuration and other mmWave configurations

that you have created.

Click New

for first-time use. For the N5251A, select Broadband

10MHz - 110GHz. For banded, define a frequency band. Select Standard

PNA to exit mmWave module operation.

Selected Configuration

Shows the currently selected configuration. Edit this field

to change the configuration name. Type a unique name using only

alphanumeric characters and underscore.

New Click to create

a new Millimeter Module configuration. A name is automatically

selected. Edit the Selected Configuration field to change the

configuration name.

Remove

Deletes a Millimeter Module Configuration.

Test

Set Properties

Selected

Test Set Select a test set to use in the current

configuration. The firmware does NOT check to ensure that the

selected test set is connected.

Route PNA

RF to rear panel "SW SRC OUT" Available

ONLY on PNA-X with option

224 or 423 AND when using N5261A and N5262A test sets.

When checked, Port 1 source is switched

to J11 and Port 3 source is switched to J8 on the PNA

rear panel. Use this configuration to quickly switch

the RF Output back to the PNA front panel.

Mixer Mode

Check to allow mixer testing using SMC.

Learn more.

Enable

Test Set RF ALC Available for N5261A and N5262A ONLY.

When checked, power is automatically leveled at the mmWave

module RF input when using the standard cables and making non-pulsed

measurements. Clear this box to use non-standard cables or when

making pulse measurements. When cleared, the following fields

become available:

Max

Power Limit The maximum mmWave module RF input is

limited to this value when Test

Set RF ALC is OFF. When you exit this dialog box

using OK, set the power

out of the PNA using the Power

and Attenuator dialog.

Power

Offset Sets the loss of the cables. The mmWave module

RF input is adjusted by this

amount. Positive offset increases the power.

Power

Slope Helps compensate for cable and test fixture

power losses at increased frequency. The mmWave module RF input

power increases as the sweep frequency increases in dB/GHz. The

slope is defined relative to the mmWave module RF input frequency.

The slope starts at 0Hz and a positive slope will increase

the power level. Range is +/- 2

dB/GHz.

Note: Changing

any of the source controls after a calibration will cause the

source power cal to be turned off. A source power cal will need

to be performed again with the new settings.

Frequency

Settings

Multiplier

RF IN RF Frequency Range (displayed in grey fields)

multiplied by this value = test port frequency range.

Multiplier

LO IN LO Frequency Range (displayed in grey field)

multiplied by this value equals the test port frequency. The

IF frequency is:

'C'

Models = 8.333 MHz PNA-X

models = 7.605 MHz

Test Port

Frequency Set the Start and Stop frequencies of the

selected configuration at the test ports. This becomes the

displayed Start and Stop frequency of the PNA.

Important

Notes

To set Test Port Frequency, first

set the appropriate Multiplier

values that are specified in your mmWave module documentation. Ensure that the RF and LO Frequencies

(highlighted below) are within the frequency range

of the sources. The PNA offers no warning if they

are NOT.

|

Source

Click a button to launch the External

Devices dialog where you can select an internal or external

source to be used for the PNA LO source or PNA RF source.

Cancel Closes

dialog box without saving changes.

OK Saves the configuration

and the PNA is Preset

before making the appropriate settings. |

Mixer Mode

Mixer measurements can be made at mmWave frequencies using SMC.

(VMC measurements are NOT supported.)

Beginning with A.09.40, mixer measurements can be made with a 2-port

test set connected to a 4-port PNA-X. This configuration yields a 2-port

mmWave system. Learn

about 2-port system connections and limitations.

Before A.09.40, The Mixer Mode checkbox could be enabled ONLY when the

number of PNA test ports matched the number of ports on the mmWave test

set. This means that an N5261A (2 port test set) could ONLY be connected

to a 2-port PNA and an N5262A (4 -port test set) could ONLY be connected

to a 4-port PNA.

Procedure

Connect your DUT to the mmWave system as described

below.

Configure this dialog (Millimeter

Module Configuration). Check Mixer

Mode, then press OK.

This presets the PNA.

Create

an SMC measurement.

Make

mixer settings. As with standard SMC measurements, only two DUT

ports can be swept in frequency. The remaining DUT port must be a

fixed frequency. See

configuration used for harmonic mixers.

Increase

power for mmWave modules that are connected directly to a PNA

port or external source.

Calibrate using the SMC

Calibration Wizard with mmWave Power Control.

Hardware Connections

for Mixer mode

The following image shows the standard connections from a N5261A or

N5262A test set port to a mmWave module.

mmWave mixers usually require that two of the three mixer ports operate

at mmWave frequencies. When Mixer Mode

is checked on this dialog (Millimeter

Module Configuration), the following restrictions apply:

On a 2 port mmWave system, only port

1 of the test set can be used as a mmWave frequency port. Port

2 can NOT be used.

On a 4 port mmWave system, only ports

1 and 3 of the test set can be used as mmWave frequency ports.

Ports 2 and 4 can NOT be used.

The SMC

parameter being measured must be within the frequency range of

the PNA or within the frequency range of the banded mmWave module.

Frequencies in between these ranges are allowed by the SMC

mixer setup dialog, but the measurement results on the screen

are NOT accurate.

Connections with a 4-port mmWave system

Upconverters

DUT Input - Connect to PNA port 2 or port 4.

DUT LO - Connect mmWave module to test set Port 3.

DUT Output - Connect mmWave module to test set Port

1.

Downconverters

DUT Input - Connect mmWave module to test set Port

1.

DUT LO - Connect mmWave module to test set Port 3.

DUT Output - Connect to PNA port 2 or port 4.

Connections with a 2-port mmWave system

Although supported, testing mmWave mixers with a 2-port system can be

challenging for the following reasons:

Testing mmWave mixers requires that two of the three

DUT ports be at mmWave frequencies.

Only test set port 1 is capable of adequately driving

a mmWave module when used as a receiver.

Therefore, the second DUT port that requires mmWave

frequencies must have the mmWave module connected directly to an external

source or a PNA second source.

When using the mmWave module as a source, only the

DC Bias and RF cable is necessary. The LO cable to the mmWave module

is NOT used. This is because the RF input frequencies are multiplied

in the mmWave module to provide the source frequencies. So a mmWave

module used as a source can use the RF cable to connect directly to

the PNA second source or an external source. About +5 dBm of RF power

is required to adequately drive the mmWave module.

Downconverters - requires two

mmWave modules as sources

DUT Input - Connect the

mmWave module to the test set port 1.

DUT LO - Connect the

RF cable of the mmWave module to an external source or the PNA (SRC2)

second source.

DUT Output - Connect to PNA port 2.

Upconverters - requires a mmWave

module as a source at the DUT

LO and a mmWave module as a receiver

at the DUT Output:

DUT Input - Connect to

PNA port 2.

DUT LO - Connect the

RF cable of the mmWave module to an external source or the PNA (SRC2)

second source.

DUT Output - Connect the mmWave module to the test

set port 1.

Measuring Harmonic Mixers

Harmonic mixers have a multiplier circuit in the LO port of the DUT.

Enter the multiplier value in the numerator of the X LO port in

the SMC

mixer setup dialog. This will provide the correct LO frequencies

out of the appropriate source.

Spectrum

Analyzer mmWave Measurements

Beginning with A.10.45.xx, spectrum

analyzer measurements can be made at mmWave frequencies using the Option

090 Spectrum

Analyzer application plus Option 093 or Option 094.

Broadband and banded mmWave measurements are supported. The test set configuration

is required for both.

Options 093 and 094 are mmWave

measurement options specific to the Spectrum Analyzer application. Broadband

measurements require Option 093 and measure from 10 MHz to ≤ 110 GHz.

Banded measurements require Option 094 and measure frequencies > 110

GHz.

Note: The IF

Response Adjustment must be performed each time a new configuration

is set up or if cables are changed.

The following procedure outlines

the steps required to set up a spectrum analyzer mmWave measurement.

Configure

the mmWave measurement using the Millimeter Module

Configuration dialog.

On the PNA

front panel, press Meas, then

[Measurement Class].

Select

Spectrum Analysis, then either:

A

Spectrum Analysis measurement

is displayed. Learn

about setting up a Spectrum Analyzer measurement.

Select

other mmWave supported measurement classes as needed.

mmWave Module Power Level Control

Beginning with A.09.40, the following TWO features are integrated into

Guided Cal:

The following table shows features that can be used to provide leveled

power to the input of your DUT for S-parameter and SMC measurements.

Feature |

Description |

Use

when... |

Use

for... |

Access

the feature... |

Receiver

leveling |

Provides

a sweep-to-sweep leveled power. |

Works

anytime. |

S-params

and SMC |

Before

or after Cal |

Use

Multiple Sensors |

Allows

several power sensors to be used to calibrate source power. |

You

require more than one power sensor to complete the source power

calibration of the measurement frequency range. |

S-params

and SA |

During

Guided Power

Cal |

Power

Table |

Build

or use a file that contains data of mmWave module output power

vs frequency. |

A

power sensor is NOT available for calibration of the mmWave modules

being used. |

S-params |

During

Std Source Power Cal |

SMC

and SA |

During

Guided Power

Cal |

Calibrate

the source at multiple power levels |

Source

power is measured using the specified power meter/sensor or PNA

receiver to construct a 2D power table. |

A

component is used in the source path which does not have NOT linear

gain or loss over frequency. |

S-params |

During

Std Source Power Cal |

S-parameter measurements

If you have one or more power sensors that spans the frequency range

of your measurement, then use the following process.

Otherwise, perform a standard Source Power Cal. Learn

how.

Using one or more power sensors

Check ALC

Enabled (if available) on the Millimeter

Module Configuration dialog.

With an S-parameter measurement active, press Cal, then Start

Cal, then Calibration Wizard,

then SmartCal.

On the following Select

Ports dialog, check Calibrate

source and receiver power, then click Next.

Important:

In the following dialog, check Use

Multiple Sensors, even if using only one sensor.

Learn

about this dialog.

Complete the Guided Cal process.

Note:

During the 'Connect a power sensor to port n'...step, the following error

message may be displayed:

The

default power level of 11 dBm is unachievable after calibration. Lower

the power before starting calibration.

This means that a high amount of loss was

measured in the path, and 11 dBm at the test ports will not be possible.

Cancel

the calibration and lower the source power level using the Power

and Attenuators dialog.

Perform a standard Source Power Cal

- S-parameter measurements

When one or more power sensors that spans the frequency range of your

S-parameter measurement are NOT available, then use the following process.

Note: Perform an

S-parameter calibration AFTER performing the following Source Power Cal.

Check ALC Enabled

(if available) on the Millimeter

Module Configuration dialog.

Press Cal,

then Power Cal then Source Cal then Options

to launch the following dialog:

See

the help topic for this dialog

If one does not already exist, create a power table

to be used to calibrate the PNA receiver. Learn

how.

Check Use a power

table and the PNA reference receiver.

Click Power Table,

then navigate to the *.prn file.

Click OK.

Check Calibrate the

source at multiple power levels.

Click Power Levels,

then enter the Max power, Min power, and Step Size at which source

power should be corrected. Be sure that the source power for your

measurement is within these power levels. Otherwise, source power

will NOT be accurate. Learn

more about this feature.

Check Calibrate the

PNA reference receiver, then click OK.

On the Source Power Cal dialog, click Take

a sweep. The output of the test set is set to Max power

and a sweep is performed to calibrate the reference receiver.

Power is dropped for several subsequent sweeps. The

calibrated reference receiver is used to fully characterize the source

power.

The entire correction table can be saved along with

the instrument state in a *.csa file. Learn

how.

Power out of the input module should be flat and accurate.

SMC Cal

Use the following calibration process to achieve accurate, leveled power

at the mmWave test ports.

With a configured SMC measurement active, press Cal, the Start

Cal, then Calibration Wizard.

At the SMC Calibration

Setup dialog, when a Thru standard is NOT available, check Independent power cals for input and output

ports (no thru).

On the Select Ports

dialog, check Calibrate source and

receiver power, then click Next.

At the following Power Cal settings dialog:

Learn

about this dialog

When you have ONE power

sensor that spans the frequency range of your SMC measurement,

then click Power Meter Settings

to configure the power sensor. There are currently NO provisions

for using multiple power sensors with SMC Calibration.

Otherwise, use the

following Power Table process.

If one does not

already exist, create a power table to be used to calibrate

the PNA receiver. Learn how.

Check Use

Power Table.

Click Power

Table, then navigate to the *.prn file. The selected

*.prn file is annotated to the dialog.

Click OK.

If you checked Independent

power cals for input and output ports (no thru), you will ALSO

be prompted to select a power table for Port 2.

Complete the Guided

SMC Cal process.

Power Table

Note: This is NOT

the same table that is used for the Calibrate

the source at multiple power levels feature.

A power table is a text file with data that describes the output power

of the module as a function of frequency. This is valid when the

mmWave module is driven at high levels (+11 dBm). This file may

have been created for you by a third party or shipped with your mmWave

Module. If not, you can create this *.prn file from the manufacturer's

specification for the mmWave module.

This file can be created manually, using a text file program such as

Notepad. Copy the header information, and create the file with two

columns, one for frequency and one for output power.

Example .prn file

Note: With Rev.

09.31, the first line of the *.prn file must have the Input power at which

these measurements were made. Otherwise, an error message appears with

the default value that will be assumed. See above image for format.

Using

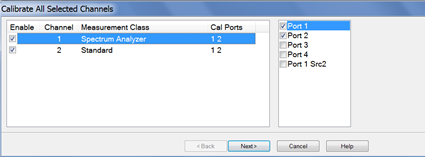

Cal All Wizard for Supported mmWave Measurement Classes

Beginning with A.10.45.xx, the

Cal All Wizard can

be used to calibrate broadband and banded configurations.

A power table can be used instead

of multiple power sensors to cover a wide frequency range. In addition,

a power table can be used when the measurement frequency exceeds the frequency

range of the power sensor (typically > 110 GHz). Refer to Power Table for information

on how to create a power table.

The

power table file name must be powertable1.prn,

where "1" corresponds to the port number. This file must be

stored in the following directory on the PNA:

C:\ProgramData\Keysight\Network

Analyzer\Configurations\<configuration name>\

where configuration name

is a directory name that is also the name of the currently selected configuration

in the Millimeter Module Configuration

dialog.

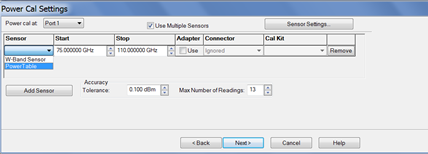

Once the power table has been

created and saved to the directory shown above, it will be listed in the

Sensor

drop down menu in the Power

Cal Settings dialog where it may be selected instead

of a power sensor.

Check

ALC

Enabled (if available) on the Millimeter

Module Configuration dialog.

Ensure

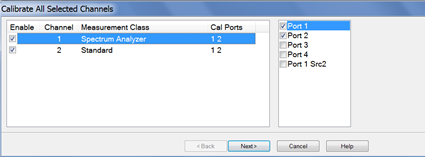

that the measurement classes to calibrate are active.

Press

Cal, then Start

Cal then Source Cal

then Cal All Wizard to launch

the following dialog showing the active measurement classes:

Select the

ports, click Next, then confirm

or change the calibration properties in the Measurement

Class Cal Properties dialog.

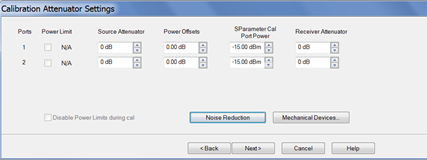

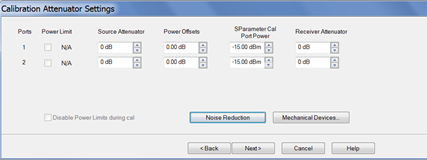

Click Next. to access the Calibration

Attenuator Settings dialog.

In the Calibration

Attenuator Settings dialog, perform the following:

Set the

attenuator settings. Learn

more.

Click on

the Noise Reduction button

to improve measurement accuracy. Learn

more.

Click on

the Mechanical Devices

button to view all switches and attenuators in the PNA. Learn

more.

Click Next, then select the DUT connectors

and calibration kits in the Select

DUT Connectors and Cal Kits dialog.

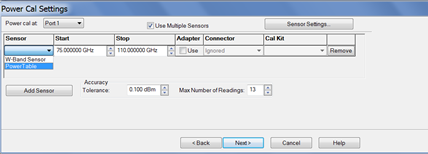

.Click Next to access the Power

Cal Settings dialog.

In the Power Cal Settings dialog, perform

the following:

Check Use

Multiple Sensors if more than one power sensor is needed

to cover the frequency range then select a sensor from the Sensor down menu.

Otherwise, check Use Multiple Sensors then select

the power table from the Sensor

drop down menu. Learn how to create a power table.

Learn

more about Accuracy

Tolerance and Max

Number of Readings.

Click

Next and follow the calibration

process until completed.