N1055A 30/50 GHz TDR/TDT Remote Sampling Head Module

The N1055A 35/50-GHz (8 ps) time-domain reflectometry (TDR) and time-domain transmission (TDT) module provides fast, accurate impedance and S-parameter measurements on high-speed designs that have up to 16 ports. The N1000A/86100D DCA-X can be configured with one to four N1055A modules to provide a 2- to 16-channel TDR/TDT measurement system that is both economical and accurate. The 2/4 port TDR/TDT remote heads can be configured with a sampler bandwidth of 35 GHz or 50 GHz, providing single-ended and differential measurement capability including True-Mode stimulus functionality.

Modules are shipped with a factory-performed TDR calibration for accurate measurements right out of the box. While a user-performed TDR calibration is optional, FlexDCA includes an integrated calibration wizard that dramatically enhances measurement accuracy by removing systematic imperfections in the instrumentation as well as the impact of adapters, cables, fixtures used to connect to the DUT. A special Keysight N4694A-HMM/HFF/HMF DC-67 GHz electronic calibration (ECal) module was developed for the DCA-TDR, making calibration fast, easy and accurate. The high-channel-count capability of the DCA-TDR solution minimizes cable reconnections and facilitates more efficient measurements in both R&D and high-volume test applications.

N1055A modules with Option FS1 include an increased module timebase sample rate (250 kSa/s) and TDR step repetition rate (1 kHz to 250 kHz). FlexDCA automatically selects the mainframe or module timebase based on the TDR DUT setup. Option FS1 is automatically included on all new N1055A modules.

This module requires FlexDCA firmware version A.04.00 or above.

Multiple module configurations require an N1000A-PLK or 86100D-ETR instrument. 86100D-ETR is required if using an N1055A module to perform a TDT measurement using a separate DCA module (for example N1045A, N1055A, 86117A, etc.) as the receiver. In this configuration, the N1000A-PLK or 86100D-ETR provides internal cabling for module synchronization.

The maximum input voltage is +2V / –1V.

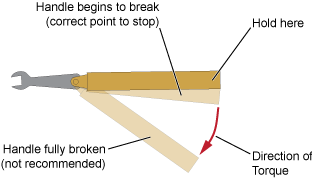

This maximum torque setting is 5 in-lb (0.56 Nm) for 1.85 mm connectors and 8 in-lb (0.9 Nm) for 2.92 mm standard connectors.

Before removing the module from the DCA-X, coil the remote head cables. This reduces the possibility of dropping one or both remote heads.

To make a direct RF connection to a remote sampling head connector

Use this procedure when connecting a cable, adapter, or some other device directly to the RF connector on the module's remote head.

The N1055A comes with either 2.92 mm or 1.85 mm port connectors, depending on the option. Both connection types can be ordered with male center contacts (female outside threads) or female center contacts (male outside threads).

- Work at a static-safe workstation.

- Visually inspect the connectors. If necessary, clean the connectors. Carefully align the connectors. The male connector center pin must slip concentrically into the contact fingers of the female connector.

- Push the connectors straight together.

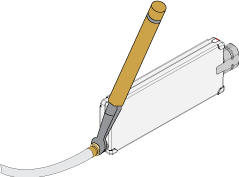

- Using a torque wrench, make the final connection between the connectors while observing the following cautions. Using the torque wrench guarantees that a connection is not too tight, thus preventing possible connector damage. It also guarantees that all connections are consistently tight each time a connection is made.

Do not twist one connector into the other (like inserting a light bulb). This happens if you turn the device body rather than the connector nut. Major damage to the center conductor can occur if the device body is twisted.

Do not tighten this connection. At this point all you want is a connection in which the outer conductors make gentle contact at all points on both mating surfaces. Very light finger pressure (no more than 2 inch-pounds of torque) is enough.

This maximum torque setting is 8 in-lb (0.90 Nm) for 1.85 mm connectors and 8 in-lb (0.9 Nm) for 2.92 mm standard connectors.

Rotate only the connector nut when you make the connection. Do not rotate the cable or adapter.

Hold the torque wrench lightly at the end of the handle.

Apply force perpendicular to the wrench handle. This applies torque to the connection through the wrench. Do not hold the wrench so tightly that you push the handle straight down along its length rather than pivoting it, otherwise you apply an unlimited amount of torque.

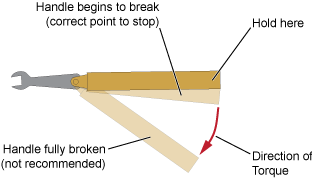

Tighten the connection just to the torque wrench "break" point as shown in the above figure. Do not tighten the connection further.

To make a indirect RF connection to a remote sampling head connector

Use this procedure when you are connecting a cable, adapter, or some other device to a device that has already been connected to the RF connector on the module's remote head. To connect an adapter cable directly to the remote head's RF connector, use the above procedure, To make an RF connection directly to a remote sampling head connector.

- Work at a static-safe workstation.

- Visually inspect the connectors. If necessary, clean the connectors. Carefully align the connectors. The male connector center pin must slip concentrically into the contact fingers of the female connector.

- Push the connectors straight together.

- Use an open-end wrench and a torque wrench to make the final connection between the connectors while observing the following cautions. The open-end wrench prevents any torque from being applied to the module's remote head connector. The torque wrench guarantees that a connection is not too tight, thus preventing possible connector damage. It also guarantees that all connections are consistently tight each time a connection is made.

Do not twist one connector into the other (like inserting a light bulb). This happens if you turn the device body rather than the connector nut. Major damage to the center conductor can occur if the device body is twisted.

Do not tighten this connection. At this point all you want is a connection in which the outer conductors make gentle contact at all points on both mating surfaces. Very light finger pressure (no more than 2 inch-pounds of torque) is enough.

Relieve any side pressure on the connection from long or heavy devices or cables. This will assure consistent torque when making the final connection.

Use your companies recommended torque setting for the type of adapter that you are using. (See general maximum torque setting guideline for adapter types)

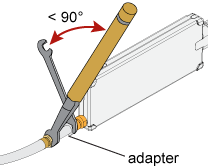

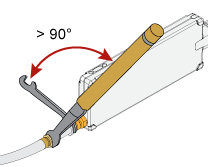

Position both wrenches within 90 degrees of each other before applying force. Wrenches opposing each other more than 90 degrees will cause a lifting action, which can misalign and damage the connection.

Rotate only the connector nut when you make the connection. Use the open-end wrench to prevent any torque from being transferred to the module's remote sampling head connector.

Hold the torque wrench lightly, at the end of the handle.

Apply force perpendicular to the wrench handle. This applies torque to the connection through the wrench. Do not hold the wrench so tightly that you push the handle straight down along its length rather than pivoting it, otherwise you apply an unlimited amount of torque.

Tighten the connection just to the torque wrench "break" point as shown in the above figure. Do not tighten the connection further.

You don't have to "fully break" the handle of the torque wrench to reach the specified torque; doing so can cause the handle to kick back and loosen the connection. Any give at all in the handle is sufficient torque.

Do not pivot the wrench handle on your thumb or other fingers, otherwise you will apply an unknown amount of torque to the connection when the wrench does reach its "break" point.

Do not twist the head of the wrench relative to the outer conductor mating plane. If you do, this will apply more than the recommended torque.

Keeping Your Test Setup Organized

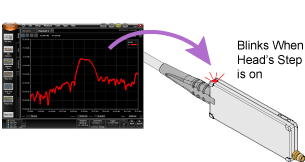

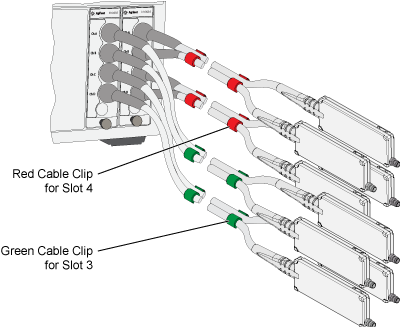

If you install four N1055A modules, each with four remote heads, you'll have a total of 16 heads and cables in your test setup. To help you manage all these cables and inputs, the module comes with a channel identification head LED, cable management clips, and head clips. The color of the head LED matches the color of the associated channel waveform.

Due to the color variation in LEDs, there may be a slight color variation between the waveform and the head's light.

Twenty-four cable clips, six each of yellow, red, blue, and green, are provided to keep differential cables together thus reducing cable tangling. The clip's color can also be used to associate a single head or differential pair of heads with a module slot.

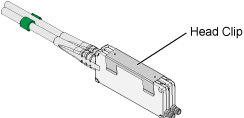

Head brackets snap over two heads to connect them together. This is especially useful when making differential measurements.

Calibration

Unlike other modules, always attach a connector saver or cable to the input connectors before calibrating an N1055A. Do not provide any signal. Because each remote head's sampler is located near the input connector, this technique improves calibration accuracy by increasing thermal stability and by eliminating sampler reflections as explained in the following text. The mass of the cable or connector saver affects the sampler thermal equalibrium of your test setup. Even small temperature changes during calibration can affect sampler bias levels which in turn affect bandwidth and amplitude accuracy. Every time a sampler fires, it sends a small amount of energy toward the remote head's input connector. This is normal and common in all instruments that employ a sampler directly connected to the input. Without a connector saver or cable connected, this energy reflects back so quickly that it affects the sampled calibration value. Any cable ≥1 inch (2.54 cm) long or even a connector saver, sufficiently extends the round trip time to eliminate this issue. It is not necessary to terminate the far end of the cable or connector saver.

In the module calibration dialog, a positive ΔT value indicates how many degrees warmer the current mainframe temperature is compared to the temperature of the mainframe at the time of the last module calibration. For N1055A modules, a positive ΔT value indicates how many degrees warmer the current remote head temperature is compared to the temperature of the remote head at the time of the last module calibration.

Stabilizing the Temperature

Each remote head represents a relatively small thermal mass and meets specifications over a ±5°C range from the last calibration temperature, measured by the internal temperature sensor and reported in the All Calibrations dialog. Factors other than the ambient air temperature will affect the operating temperature of the remote head. These factors include air currents and the temperature and thermal mass of objects in contact with the remote head. You must ensure the temperature of the N1045A module is stabilized prior to calibrating the module and making measurements. As with all plug-in modules, the temperature is stabilized after 1 hour of continuous operation. The preferred method to stabilize the temperature of the N1045A is to set up the module and remote heads in the configuration or fixture that will be used to make measurements. This includes connecting the device under test (DUT) to the remote heads.

When the internal temperature is stabilized, disconnect the DUT and perform a module calibration. If you move the remote head to a location that is thermally different than the location in which it was stabilized, you will have to wait for the temperature to stabilize again, and then calibrate the module before making measurements. For example, if the remote head is placed on a workbench for an hour, and then mounted on a cool metal fixture to make measurements, the temperature of the sampling head will begin to drop, possibly out of the ±5°C range.

The temperature, thermal mass, and thermal conductivity of the DUT will affect the internal temperature of the remote head. A DUT that is significantly different in temperature than the remote head will add thermal mass, which may increase or decrease the temperature stabilization time.

Recommendations

- Ensure that the remote head's entire surface is never outside a 15°C to 35°C temperature range.

- Verify temperatures using a thermometer. The hottest locations are likely close to the input connector and the center of the head's sides.

- If possible, leave an air gap between remote heads.

- Use forced airflow.

- When designing a cooling system, anticipate that each remote head can generate between 1 and 3 Watts of heat.

- Although the module's remote-head cable can sustain at least a 100 °C surface temperature, the cable's color might degrade if exposed to high temperatures for long periods of time. This does not damage the cable.

Monitoring a Head's Thermal Equilibrium

To monitor the thermal equilibrium of a remote head:

- Click Tools > Calibrations on FLexDCA's menu to open the Calibrations dialog.

- Click the N1055A tab.

- Click the Details button for the remote head's channel. This views the following Vertical Calibration Details:

- Temperature change in °C for the remote head since the last calibration.

- "The temperature has changed by more than 5.00°C" is displayed if module needs to be calibrated.

Wait one minute then open the All Calibrations dialog again. If the temperature changes more than 0.5°C, the channel is not at thermal equilibrium.

To monitor the remote head's change in temperature using remotely, use the :CALibrate:CHANnel:STATus:DTEMperature? query. You can also locate the command in the Interactive SCPI Command Tree and click the Query button.

For very high speed signals (for example, 10 ps edges), if thermal equilibrium has not been reached, the rising and falling edges will appear to move on the horizontal axis of the display screen. If during the one minute of elapsed observation time the remote head is not moved, but the displayed signal shifts to the left or right, the channel is not thermally stable. The remote head cable should be mechanically stabilized during this observation, otherwise the displayed signal may show some movement due to slight phase changes in the cable.

Secure the Remote Heads

To prevent the mass of the cable from pulling the remote head off a benchtop or out of a test fixture, five threaded mounting holes are provided as shown in the following picture. The five holes use M3 x 0.5 mm threads. Using these holes, you can attach the head to your own custom fixture. Or you can use an accessory universal bracket (N1027A-1PB) to attach the head to a probe positioner. It is important to consider the thermal properties of the remote head when designing a fixture. Larger fixtures increase the thermal mass of the remote head, which increases the time the remote head takes to reach thermal equilibrium.

The nominal length of the remote head cables is 1270 mm as measured from the module's front panel to the remote head's casing.

The maximum torque for the mounting screws is 9 lb-in.

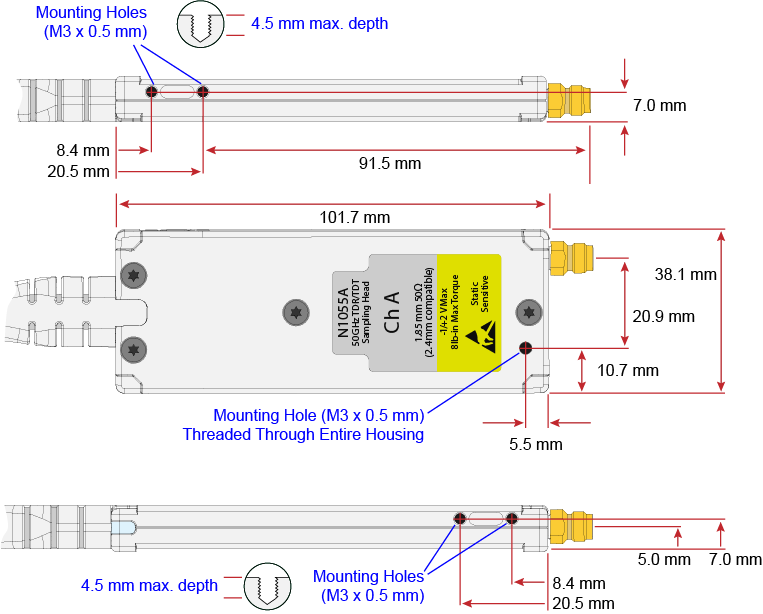

Figure. Dimensions for Mounting Holes and Screws

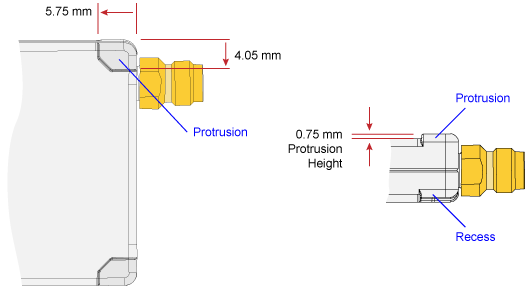

Figure. Dimensions of Head Protrusions

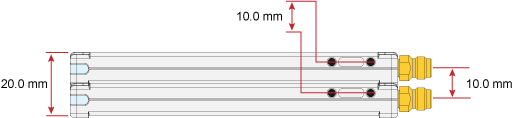

Figure. Dimensions for Two Heads Joined Together

Stability of the Remote Head Cables during Measurements

The remote head cable carries the high frequency content of the timebase signal. Changes to the physical shape of the cable (for example, bending or twisting) may horizontally skew the signal on the display screen. Changes in the shape of the cable cause variations in the effective electrical length of the cable, which translates directly to horizontal timing variations. This is important to be aware of when making jitter measurements. Vibration is similar to cable movement. Vibrating the cable may also horizontally skew the signal on the display screen. Temperature changes can also result in timing variations by adding femto or even pico seconds of change in electrical length. This electrical length change is due to the thermal expansion and contraction of the remote head cable. Use tape, cable ties, and the provided cable clips to stabilize the cables to minimize the affects of phase shift.

As with all microwave connectors, take extreme care to protect the 1.85 mm input connector. Torque forces in excess of 8 lb-in (90 N-cm) and any shear or axial forces on the 1.85 mm input connector must be avoided. Use Keysight torque wrench part number 8710-1582. Always use two wrenches when connecting or disconnecting cables or devices from the 1.85 mm connector. Use one wrench on the 1.85 mm connector of the remote head, and the other wrench on the cable (adapter, attenuator, or DUT) attached to connector. If you over-torque the RF connector, the connector may unscrew from the remote head. This will require service. If a connector loosens from the remote head, contact an Keysight service center for repair.

Supplied Accessories

| Description | Quantity |

|---|---|

| Module configuration card. | 1 |

| Torque Wrench. 8 lb-in, 5/16 in | 1 |

| Protective Caps for 2.92 mm, female (provided with options 32F and 34F. | 2 or 4 |

| Protective Caps for 2.92 mm, male (provided with options 32M and 34M. | 2 or 4 |

| Protective Caps for 1.85 mm, female (provided with options 52F and 54F. | 2 or 4 |

| Protective Caps for 1.85 mm, male (provided with options 52M and 54M. | 2 or 4 |

| 1.85 mm protective cap for 04F and 04M options | 4 |

| Cable Management Clips. Six each yellow, green, blue, red. | 24 |

| Remote Head Clip | 2 |

In the following tables, the terms (m) and (f) indicate the type of center contact, male or female respectively.

1.85 mm and 2.4 mm connectors are mechanically compatible.

Options

| Option | Description |

|---|---|

| N1055A-32M | 35 GHz BW, 2 Channel Remote Head with 2.92 mm (m) connectors. Upgradable from 2 channel to 4 channel after purchase (return to Keysight). Upgradable from 35 GHz to 50 GHz after purchase (return to Keysight). |

| N1055A-32F | 35 GHz BW, 2 Channel Remote Head with 2.92 mm (f) connectors. Upgradable from 2 channel to 4 channel after purchase (return to Keysight). Upgradable from 35 GHz to 50 GHz after purchase (return to Keysight). |

| N1055A-34M | 35 GHz BW, 4 Channel Remote Head with 2.92 mm (m) connectors. Upgradable from 35 GHz to 50 GHz after purchase (return to Keysight). |

| N1055A-34F | 35 GHz BW, 4 Channel Remote Head with 2.92 mm (f) connectors. Upgradable from 35 GHz to 50 GHz after purchase (return to Keysight). |

| N1055A-52M | 50 GHz BW, 2 Channel Remote Head with 1.85 mm (m) connectors. Upgradable from 2 channel to 4 channel after purchase (return to Keysight). |

| N1055A-52F | 50 GHz BW, 2 Channel Remote Head with 1.85 mm (f) connectors. Upgradable from 2 channel to 4 channel after purchase (return to Keysight). |

| N1055A-54M | 50 GHz BW, 4 Channel Remote Head with 1.85 mm (m) connectors. |

| N1055A-54F | 50 GHz BW, 4 Channel Remote Head with 1.85 mm (f) connectors. |

| N1055A-FS1 | Fast sample rate. Sample rate (module timebase) is 250 kSa/s (characteristic). TDR step repetition rate is 1 kHz to 250 kHz (characteristic). Refer to N1055A module specifications for details. |

Available Calibration Kits

| Model | Description |

|---|---|

| Electronic Calibration (ECal) Modules | |

| N4694D-0DC | ECal module, DC to 67 GHz, 1.85 mm |

| N4694A-00M | ECal module, DC to 67 GHz, 1.85 mm, male-male |

| N4694A-00F | ECal module, 10 MHz to 67 GHz, 1.85 mm, female-female |

| N4694A-M0F | ECal module, 10 MHz to 67 GHz, 1.85 mm, male-female |

| Mechanical Calibration Kits | |

| 85033D | 3.5mm calibration kit, 30 kHz to 6 GHz |

| 85033E | Standard mechanical calibration kit, DC to 9 GHz, 3.5 mm |

| 85052B | Standard mechanical calibration kit, DC to 26.5 GHz, 3.5 mm |

| 85052C | Precision mechanical calibration kit, DC to 26.5 GHz, 3.5 mm |

| 85052D | Economy mechanical calibration kit, DC to 26.5 GHz, 3.5 mm |

| 85056A | Standard mechanical calibration kit, DC to 50 GHz, 2.4 mm |

| 85056D | Economy mechanical calibration kit, DC to 50 GHz, 2.4 mm |

| 85056K | Mechanical calibration kit, DC to 50 GHz, 2.4 mm and 2.92 mm |

| 85058B | Standard mechanical calibration kit, DC to 67 GHz, 1.85 mm |

| 85058E | Economy mechanical calibration kit, DC to 67 GHz, 1.85 mm |

Available Accessories Specific to the N1055A Module

| Description | Item |

|---|---|

| Replacement cable management clips. Quantity 24, six each yellow, green, blue, and red. | N1027A-1CL |

| Replacement head clip. Quantity 1. | N1027A-2CL |

| Universal probe-head-to-probe-positioner bracket. The bracket is designed to fit over 1/4-inch diameter dowel on probe positioner. | N1027A-1PB |

| Protective cap for 1.85 mm female connector | N1027A-1CF |

| Protective cap, 1.85 mm male connector | N1027A-1CM |

| Adapter, 1.85 mm (f-f) | N1027A-1FF |

| Adapter, 1.85 mm (m-f) | N1027A-1MF |

| Adapter, 1.85 mm (m-m) | N1027A-1MM |

| Adapter, 2.4 mm (m) to 3.5 mm (m) | N1027A-23A |

| Adapter, 2.4 mm (f) to 3.5 mm (f) | N1027A-23B |

| Adapter, 2.4 mm (m) to 3.5 mm (f) | N1027A-23C |

| Adapter, 2.4 mm (f) to 3.5 mm (m) | N1027A-23D |

| Coaxial cable. 1.85 mm, M/M, 67 GHz, 10 cm long | N1027A-1C1 |

| Accessory case | N1027A-3AC |

| Module storage case | N1027A-3MC |